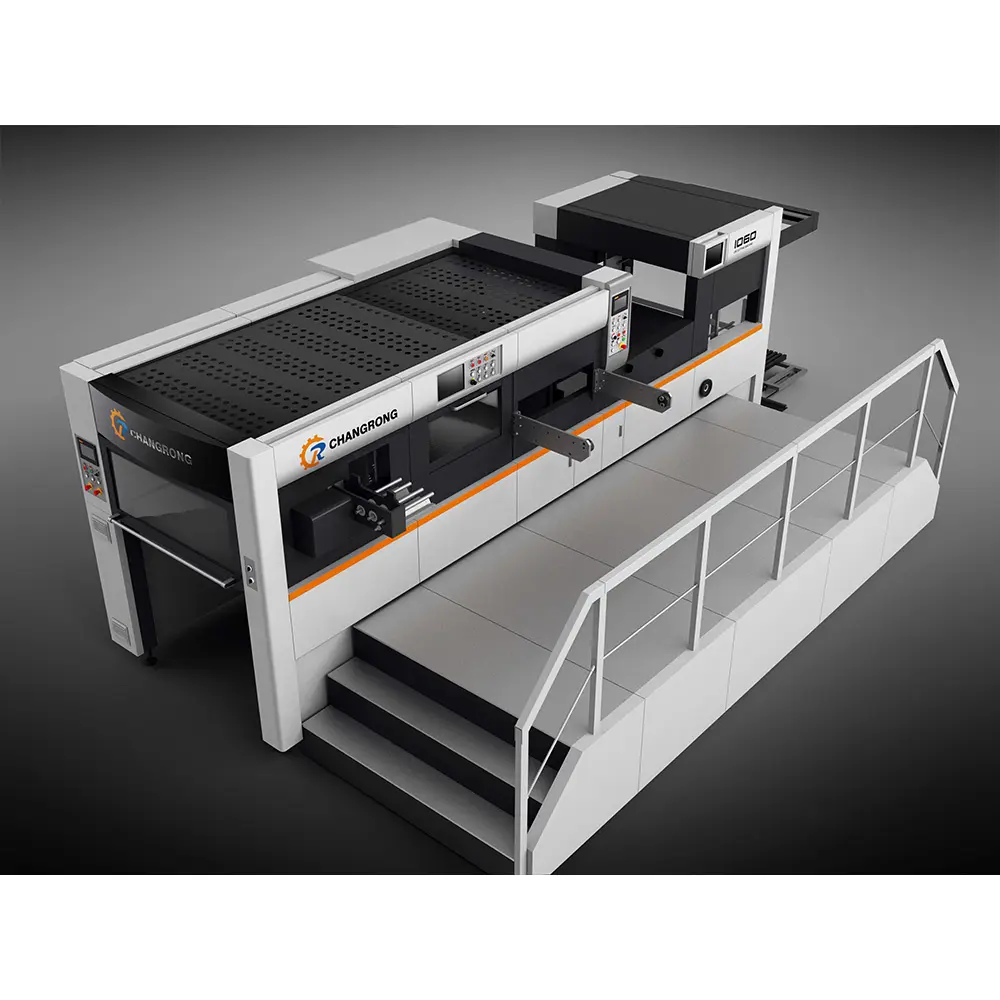

1060 Automatic Three Longitudinal And Two Lateral Foil Stamping Machine

Variable frequency heating system

Motor

Electrical box

Foil placement rack quick foil changing device

Imported SKF bearings

Human-machine interface

Paper feeding section

Siemens servo

Siemens servo controller

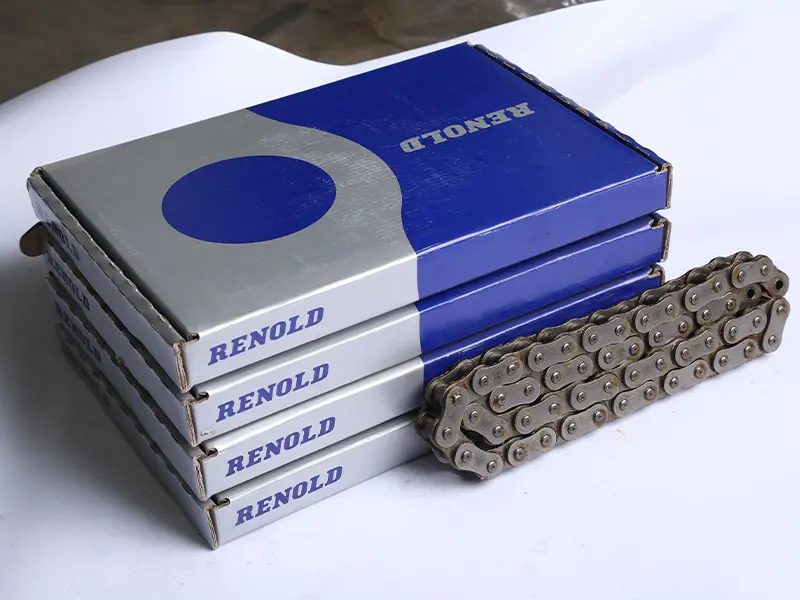

British Renode chain

Main motor frequency converter

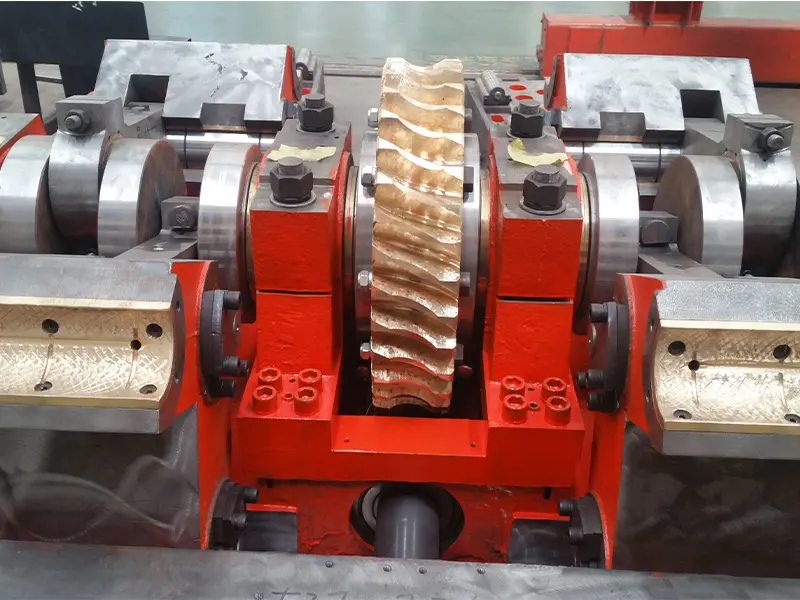

Main engine turbine

Feeding unit

|

No. |

Name of Part |

Foto |

|

1 |

Feeder: The feeder utilizes advanced European technology with four suction cups and four blowers. The suction cups are adjustable to ensure stable conveying of different types and shapes of paper without stopping the machine. The easy-to-adjust feature allows the paper to be thinned for accurate conveying, providing a reliable guarantee for high-quality printing and paper processing. |

|

|

2 |

An auxiliary blowing device used for thin paper feeding, which utilizes the buoyancy effect generated by airflow to effectively separate adhered paper and avoid paper jams caused by friction or static electricity. |

|

|

3 |

Sheet Separating Blowing Device at Transport Bracket |

|

|

4 |

Side Lay: The side lay,after special desige,contains push and pull. You can choose the appropriate one based on different products without the need to replace parts. When working sideways, the paper hardly moves and the paper is not worn, which helps to transfer the paper at high speed and provides us with efficient work |

|

|

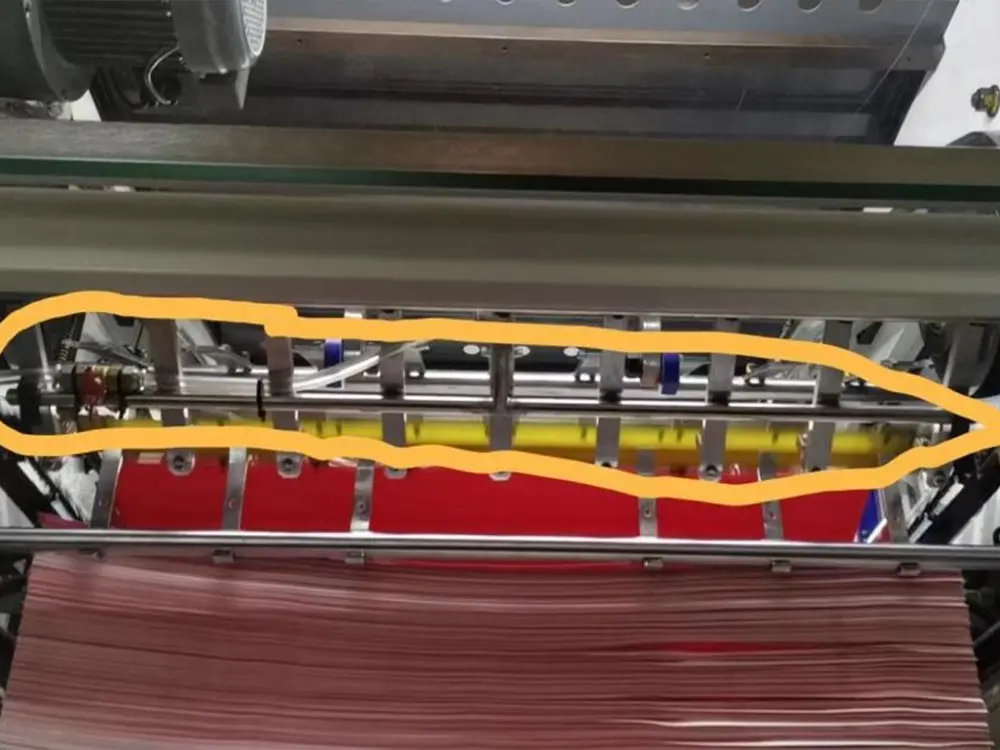

5 |

Gripper bar and Chain: The clamping bar is made of special super-hard aluminum alloy, treated with anodic oxidation process, forming a dense wear-resistant layer on the surface, which can maintain high rigidity in complex adjustment operations, realize accurate die-cutting, and control the error within a very small range. The main chain of the spacer utilizes innovative reinforcement technology, which improves the strength of the chain by about 45% compared with the conventional chain and effectively reduces deformation and wear in the transmission process, which not only significantly improves the operating precision and stability, but also extends the service life of the core components of the equipment, providing reliable support for efficient and long-lasting production operations. |

|

Main Transmission

|

No. |

Name of Part |

Foto |

|

|

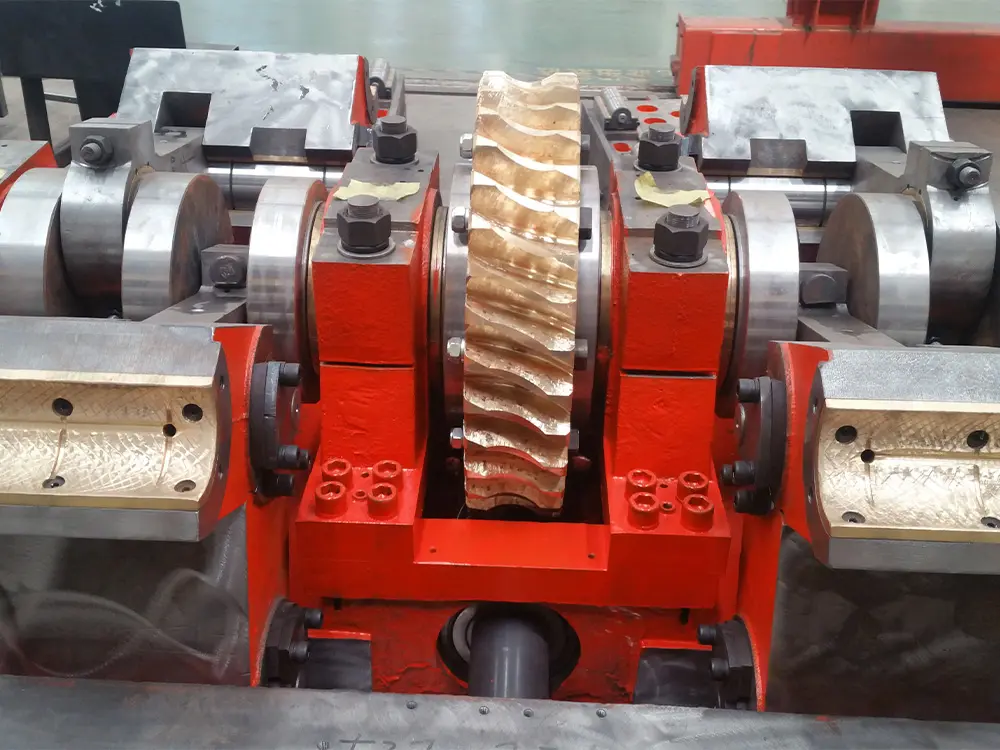

1 |

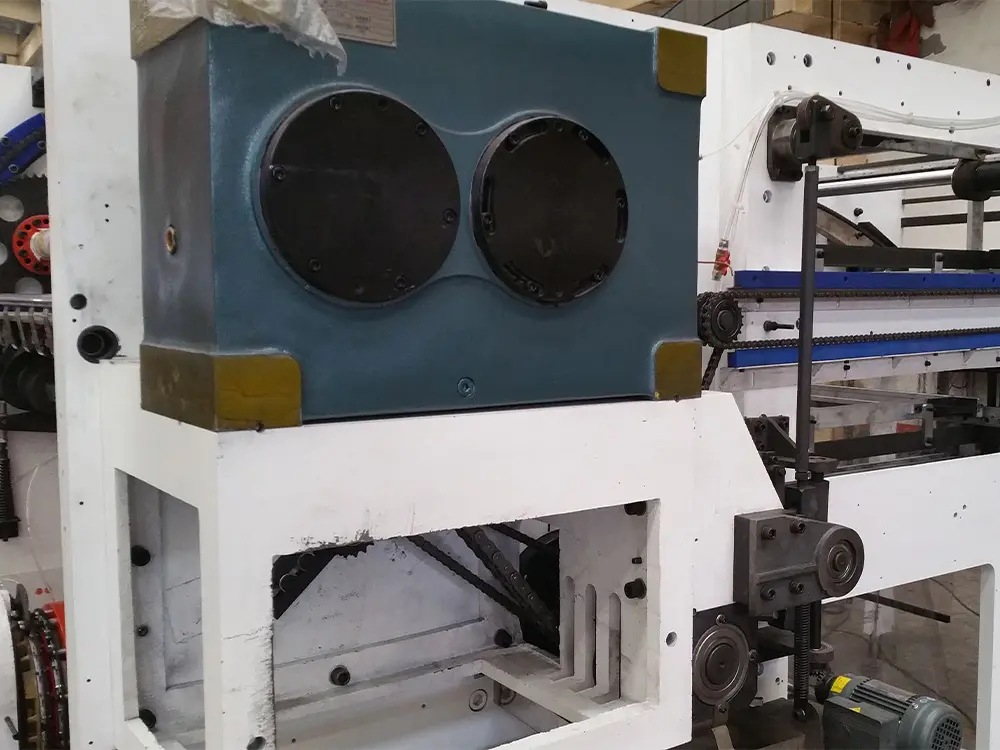

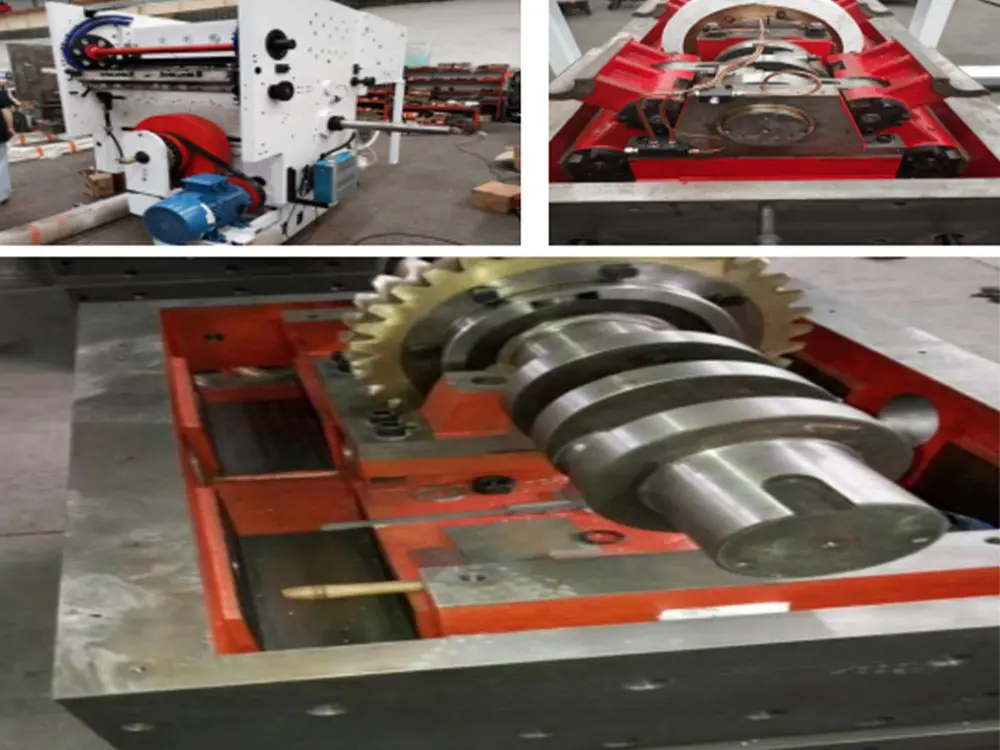

Main Transmission:The worm shaft is made of German imported alloy copper material, which has excellent mechanical performance, high precision, and special wear resistance through precision machining. The bent shaft and worm adopt forging |

|

|

|

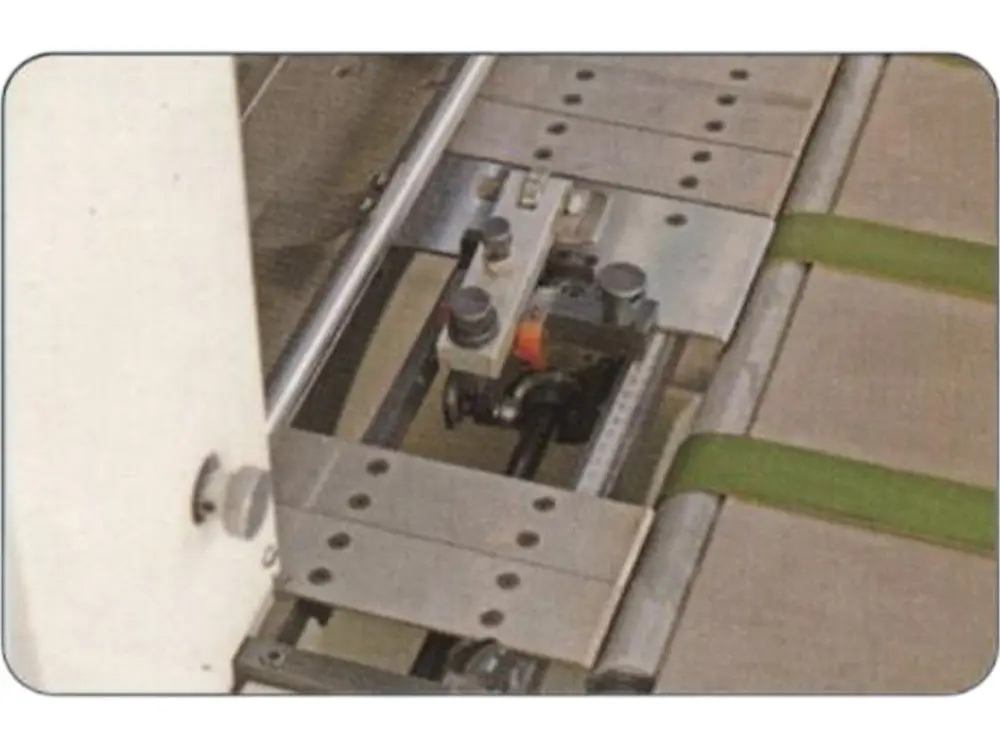

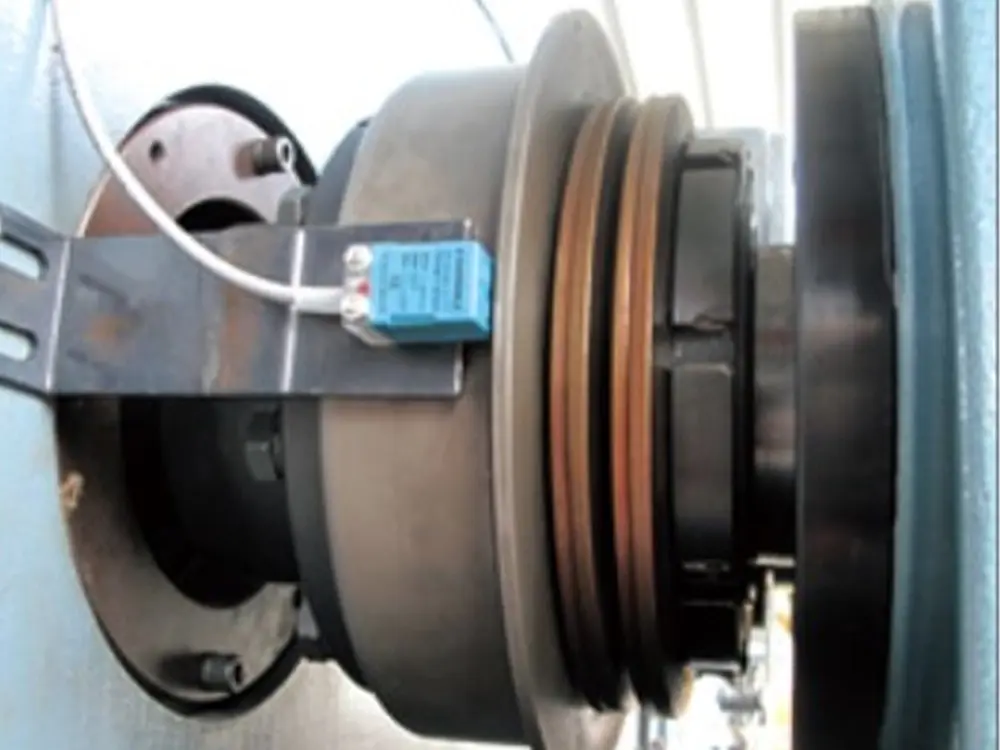

2 |

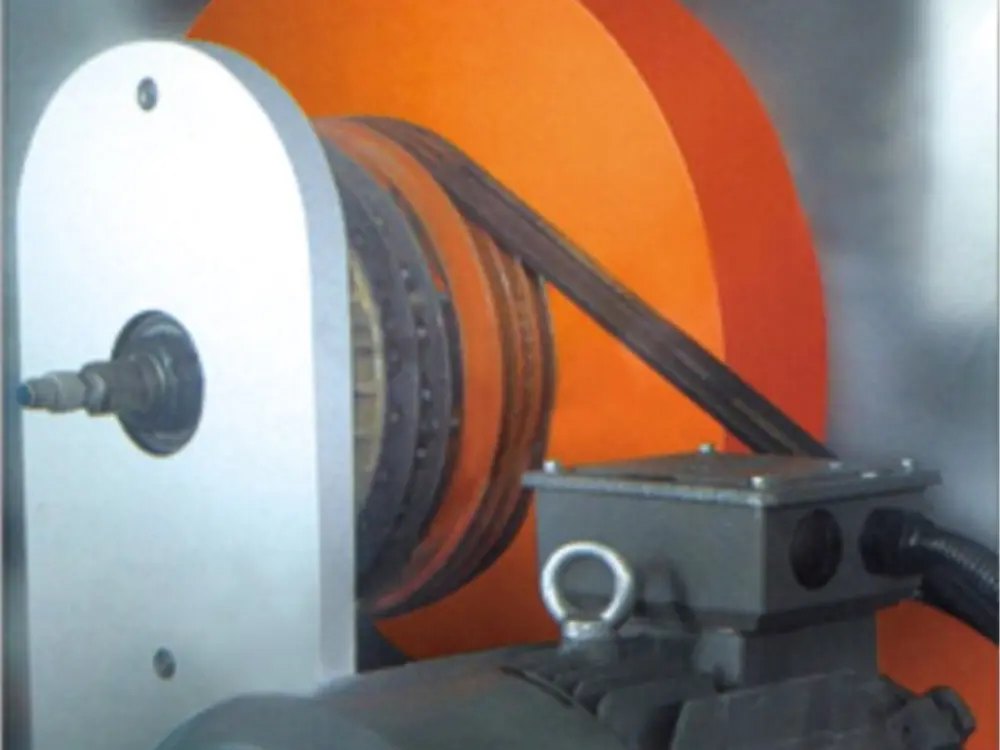

Pneumatic clutch: Deeply integrated with European manufacturing processes, the core components are made of high-quality components to ensure excellent performance. Reduce noise and aerodynamic impact, ensure stable and safe operation. Meets European export standards. The use of Italian yuyi's clutch is more stable, greatly improving equipment safety and operational comfort. |

|

|

|

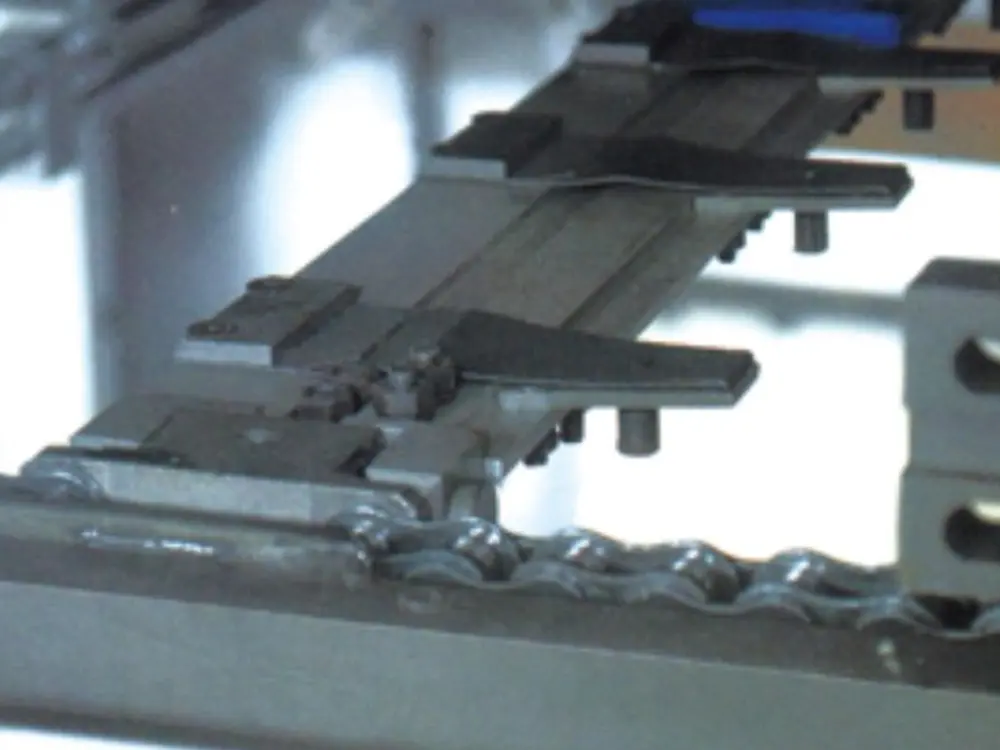

3 |

Main Chain drive:The main chain is driven by an intermittent mechanism manufactured by Renault in Germany and Taiwan, which improves die-cutting accuracy, ensures equipment safety, avoids machine damage, improves service life, and provides a solid guarantee for the long-term efficient operation of the equipment. |

|

|

|

4 |

Anti-explosion OF Brazilian WEG |

|

|

|

5 |

High quality Siemens sensors |

|

|

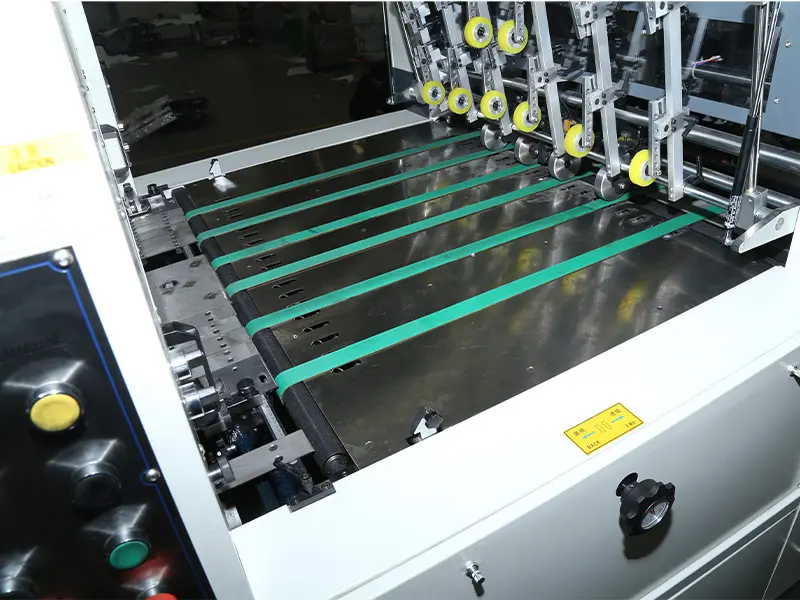

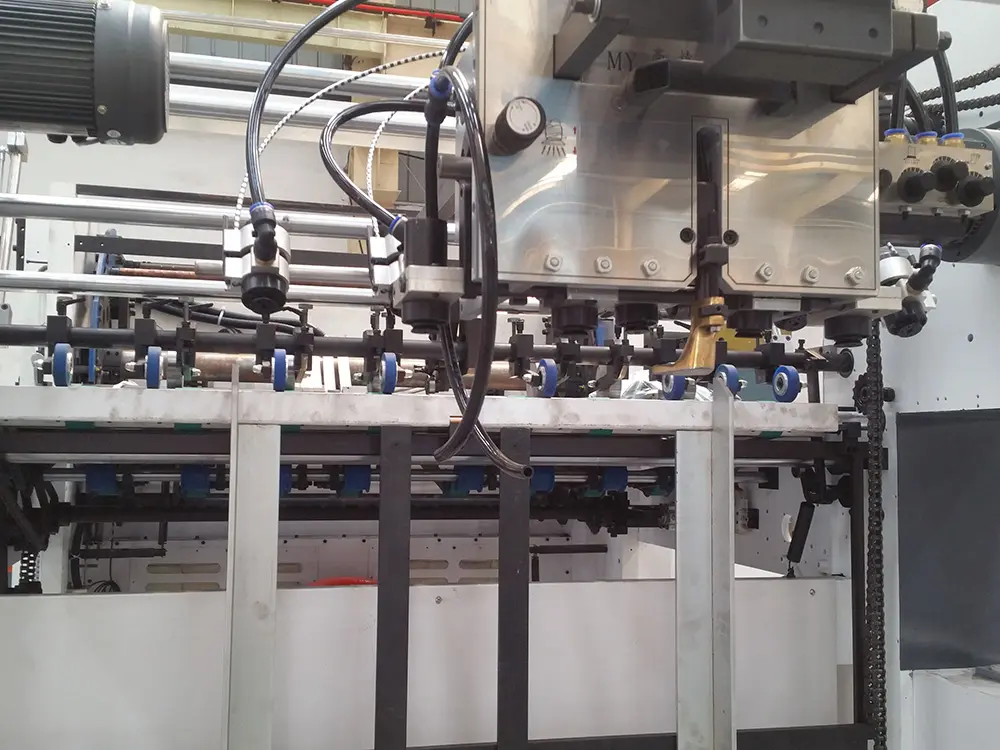

Die-cutting part

|

No. |

Name of Part |

Foto |

|

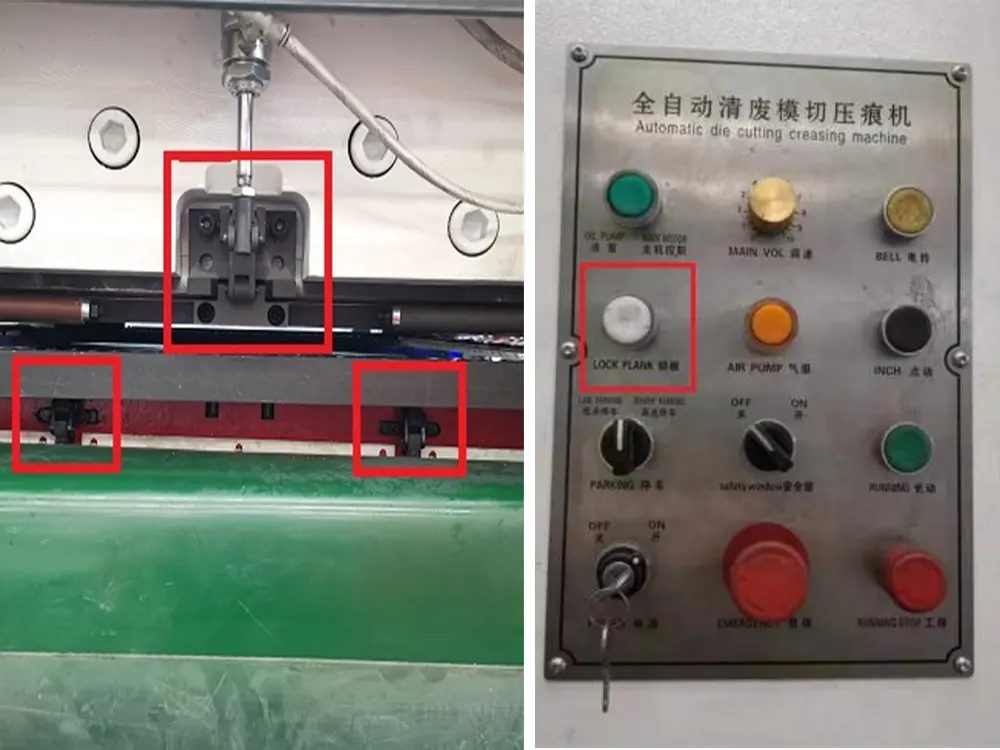

1 |

Die-cutting part: The design of the die cutting section deeply integrates safety concepts and humanized considerations, as well as the design of devices that are easy to move and rotate, making board installation and placement faster and more convenient. Pneumatic stability is restored. Uninterrupted feeding and conveying device. |

|

|

2 |

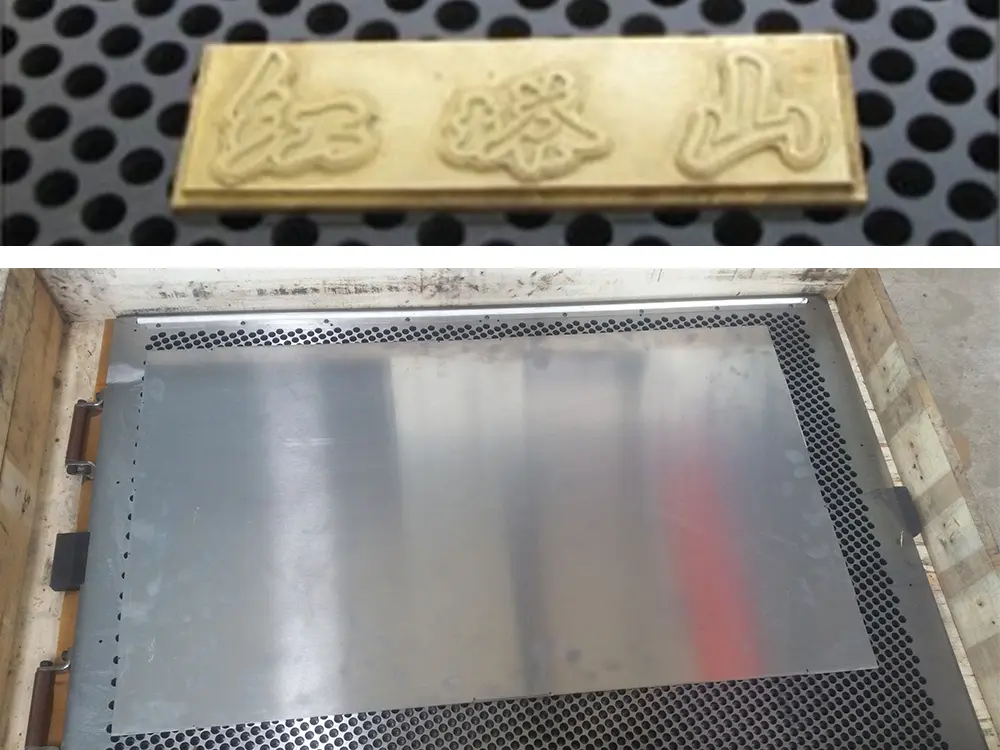

Fixed in a central positioning line; Knife plate around the screw fixed clamp; Choose claw screw positioning and fixing; |

|

|

3 |

Paper Flattering Device in Diecutting |

|

|

4 |

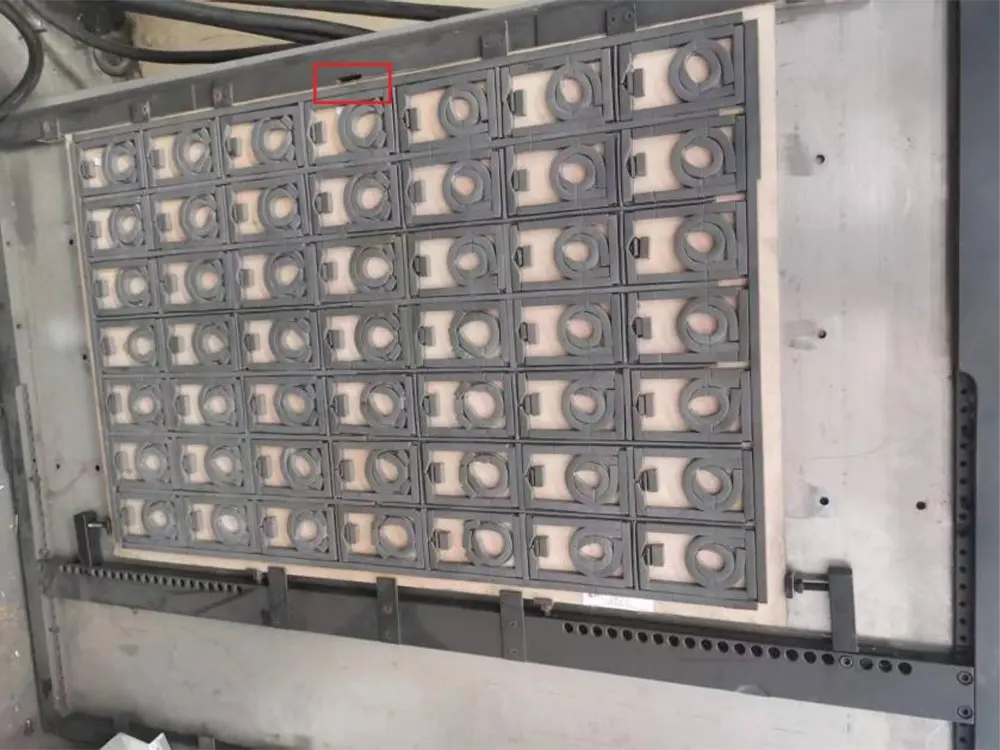

HONEYCOMB CHASE:The honeycomb chase is made of high heat resistant steel with excellent dimensional stability.The honeycomb chase is designed to accept stanard toggle hooks which are used for accurately positioning the stamping dies.Two Teflin rollers on the honeycomb chase are designed to separarte the foil from the chase;in addition these devices ate designed to eliminate damage of foil when the chase is at high temperature. |

|

|

5 |

Flexible Foil Unwinding Rack: So smart design to keep the rack flexible,making operation so easy,quick,safe and convenient; in order to keep the stamping precision,the foil unwinding rack is adjustable at tension control, so as to keep foil unwinding smooth,accurate and easy. |

|

|

6 |

The device is equipped with a locking plate with a fast automatic locking device, and its lower locking plate also has a fast locking function. One key locking button, lock when the light is off, light on the loose, can realize the rapid locking and unlocking, which greatly reduces the time required for equipment debugging. |

|

|

7 |

In terms of pressure adjustment, the system relies on advanced electric control technology, through the screen can realize the precise adjustment of pressure, including electric pressure increase and decrease operation. |

|

Delivery section

|

No. |

Name of Part |

Foto |

|

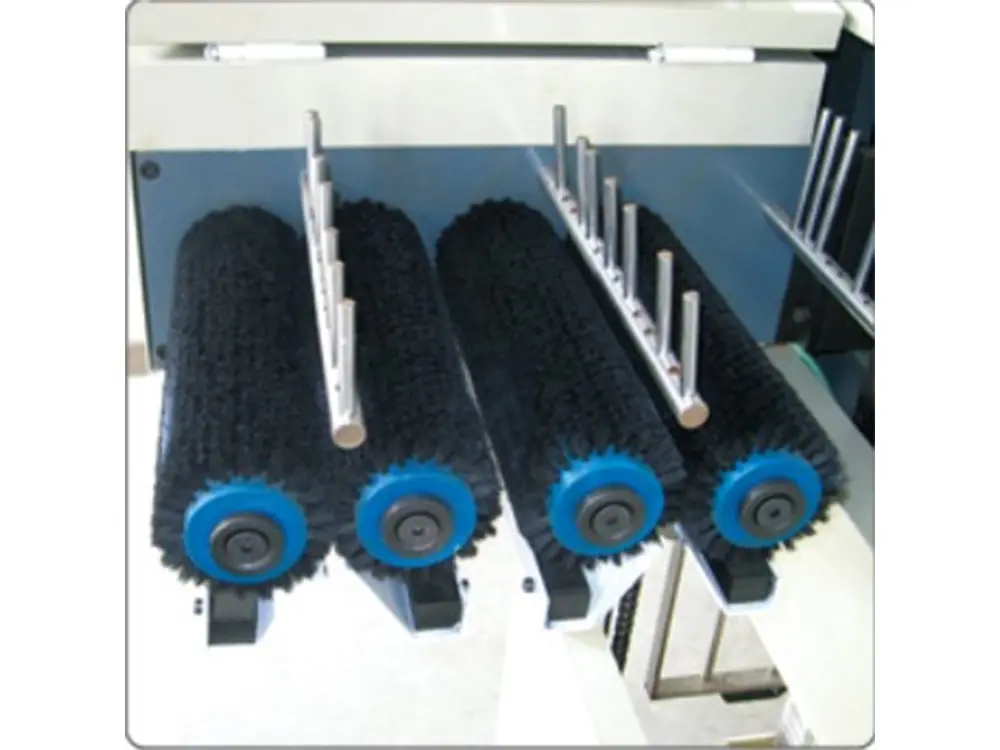

1 |

Delivery section: Paper dampening and deceleration is achieved by means of a mechanical feeder brush mechanism. This specialized design significantly enhances the performance of the sheet locking mechanism, enabling it to secure the top frame more firmly and precisely. Saves time. Safer and more reliable |  |

Host structure of equipment

|

No. |

Name of Part |

Foto |

|

1 |

Host structure of equipment |

|

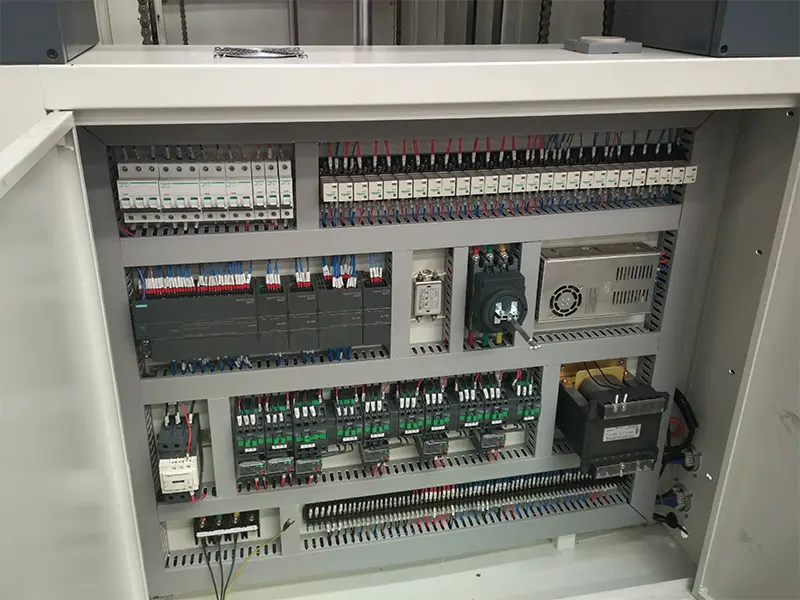

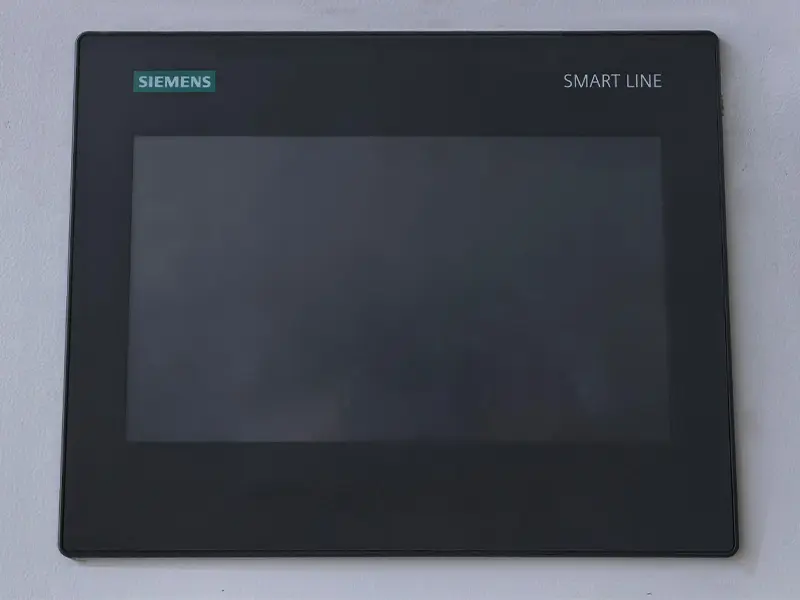

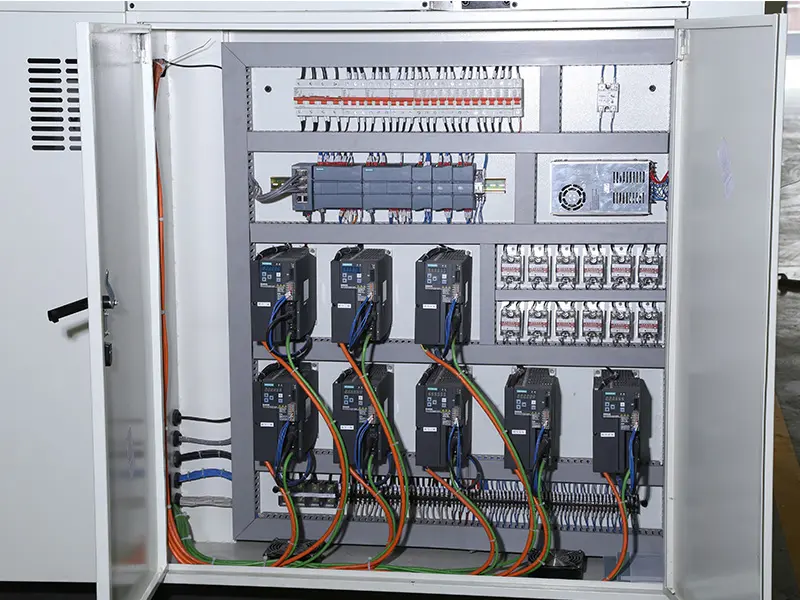

Electrical part

|

No. |

Name of Part |

Foto |

|

1 |

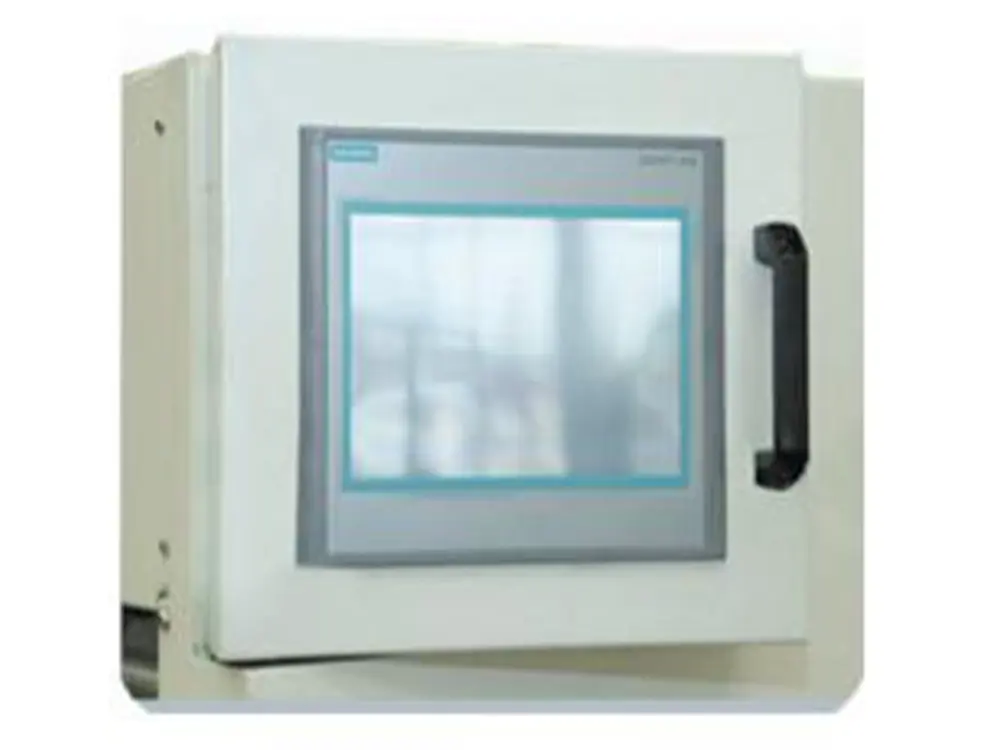

Man-machine interface: This equipment utilizes imported high-resolution human-machine interface. The interface enables real-time monitoring and accurate display of the machine's operating status. At the same time, it can also provide detailed operation methods and solutions for machine adjustment and troubleshooting, which helps the operator to deal with relevant problems quickly and accurately, and guarantees the stable operation of the machine. |

|

|

2 |

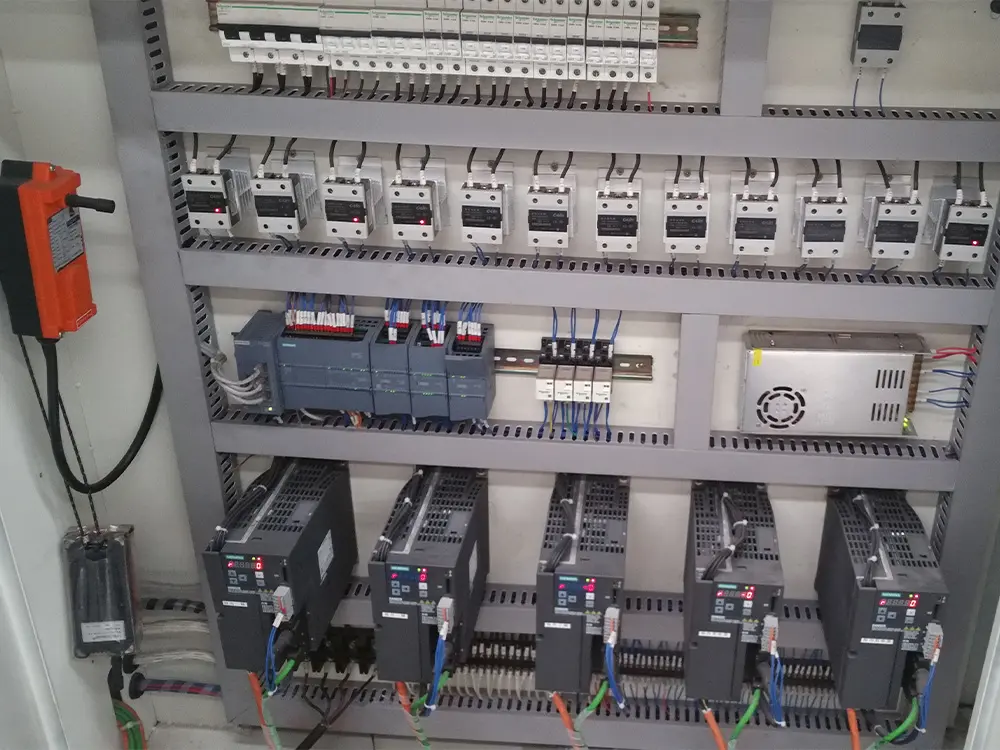

Electrical Unit: The machine is controlled by Siemens PLC, frequency conversion. Various electrical components, the switch is used in Japan, France, Taiwan and other well-known brands. Precise operation control and stable performance provide strong technical support for the long-term stable operation of the equipment. |

|

|

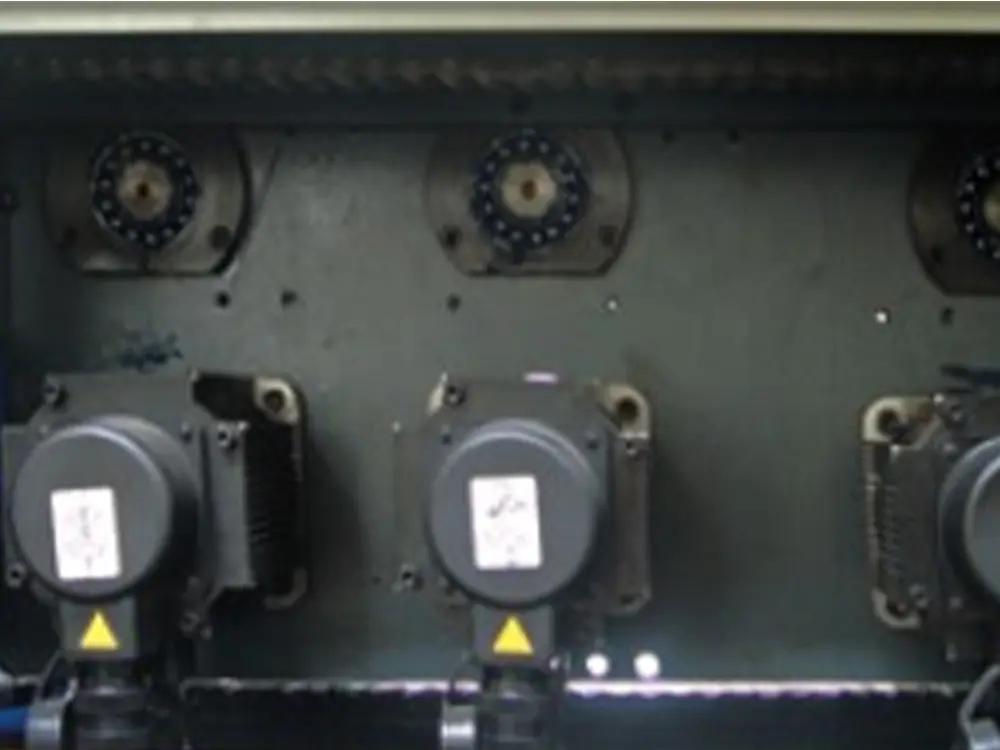

3 |

Foil Unwinding Motor System:Adopting Siemens motor and servo system, the system has active and fast response mechanism, which can quickly execute various operations, Siemens program controller; at the same time, it has high-precision positioning function, which can ensure accurate positioning of the aluminum foil in the process of unwinding; and it can realize high-speed feeding of the foil to effectively improve the production efficiency. |

|

|

4 |

Waste Foil Collecting Brush Wheel Unit: Under the control of Siemens servo motor, the speed of brush wheel unit can be flexibly adjusted according to the actual production demand, with excellent speed regulation performance, matching with the stamping speed, so as to keep the foil tension constant, effectively avoiding the negative impact on the production due to the fluctuation of tension. |

|

|

5 |

Foil Breaking Supervision System: The foil breakage monitoring system, as the “intelligent guardian” of stamping production, reacts positively and performs reliably to minimize the undesirable losses caused by foil breakage in the stamping process |

|

|

6 |

Torsion Limiter: very sensitive, effectively guaranteeing the safe operation of the machine, minimizing personal injuries to the operator, and constructing a solid and reliable protective barrier for safe production. |

|

Technical Data

| Maximum paper feeding size | 1060mm×760mm |

| Minimum paper feeding size | 420mm×350mm |

| Max die cutting size | 1050mm×750mm |

| Max stamping size | 1020mm×750mm |

| Gripper margin | ≥6mm |

| Inner chase size | 1120mm×786mm |

| Stock range | 80-2000g/m2 paper 0.1-2mm paper≤4mm corrugated |

| Die cutting accuracy | ≤±0.075mm(die cutting and stamping) |

| Max die cutting force | 300tons |

| Max die cutting speed | 5500p/h |

| Max feeder pile height | 1600mm(wooden pallet included) |

| Max delivery pile height | 1500(wooden pallet included) |

| Wide dimension of in longitudinal | 250mm |

| Stamping shaft number | Five shaft |

| Air requirement | 12 heating zones, 40-180℃ Adjustable |

| Net weight approx | About 18tons |

| Main motor wattage | 11KW |

| Full load wattage | 54.5KW |

| Overall dimension | 7500mm(L: Pre-load paper device included)×4000mm(W: Platform included)×2700mm(H) |

Electrical equipment layout

| PLC computer program controller | SIEMENS of Germany |

| Man-machine interface | SIEMENS of Germany |

| Principal machine transmission | anti-explosion OF Brazilian WEG |

| Contacts | SCHNEIDER |

| Optoelectronic switch | OMRON of JAPAN |

| Air switch | SCHNEIDER |

| Bearing | Swedish SKF |

| Transducer of main machine | SIEMENS of Germany |

| Reducing box | CPG of Taiwan |

| Main chain | RENORD of Germany |

| Intermittent mechanism | Taiwan |

| Server system | SIEMENS of Germany |

| Linear guide rail | HIWIN |

| Host protect | Torque protector |

| Temperature control system | SIEMENS of Germany |

| Oil supply system of main machine | WEILIANG of Taiwan |

description2