Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the evolving landscape of printing and packaging, choosing the right Hot Foil Embossing Machine is crucial for enhancing product appeal and meeting customer demands. Industry expert John Smith, a recognized consultant in printing technologies, emphasizes, “The right embossing machine not only elevates your brand's status but also boosts operational efficiency.” As businesses endeavor to create unique packaging solutions that stand out in a competitive marketplace, understanding the features and benefits of various embossing machines becomes paramount.

This guide aims to assist business owners in navigating the complexities of selecting the ideal Hot Foil Embossing Machine tailored to their specific operational needs. From analyzing production requirements to considering budget constraints, the decision-making process can be daunting. However, by leveraging expert insights and evaluating key machine specifications, businesses can confidently invest in a solution that aligns with their branding strategy and production goals.

As we explore the factors influencing your choice of a Hot Foil Embossing Machine, it is essential to keep in mind how these machines can transform your printing capabilities and strengthen your market position. With the right knowledge and resources, you can unlock the full potential of embossing technology for your business.

Hot foil embossing is a sophisticated printing technique that enhances the visual appeal of products through the application of metallic foils. This process involves applying heat and pressure to transfer the foil onto a substrate, creating eye-catching designs and text that appeal to consumers. According to the Smithers Pira report, the global demand for hot foil stamping technology is projected to reach $3 billion by 2025, reflecting the increasing interest in high-quality finishing solutions across various industries.

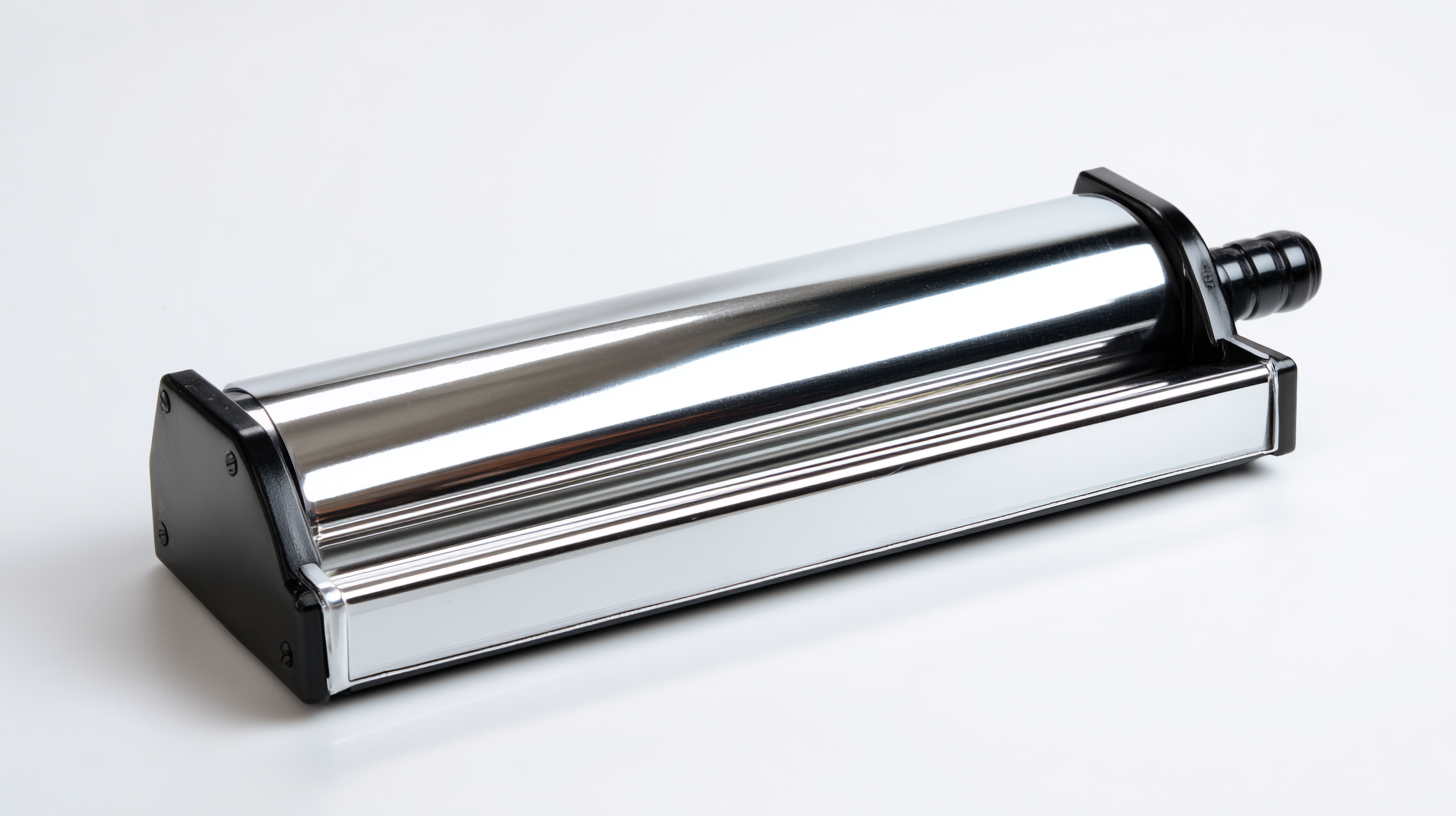

Understanding the basics of hot foil embossing machines is crucial for businesses looking to invest in this technology. Key components include the heat source, pressure mechanism, and foil feed system. Businesses must consider their production needs, with machines available for both small-scale and mass production. For instance, automatic machines can achieve high output rates, making them suitable for larger businesses, while tabletop devices can cater to smaller operations with lower volume requirements. The right choice not only boosts efficiency but also ensures optimal quality in the final product, thereby enhancing brand value and customer satisfaction.

When selecting the best hot foil embossing machine for your business needs, it’s essential to focus on key features that will enhance your production capabilities. First, consider the machine’s heat distribution and temperature control systems. A uniform heating mechanism allows for consistent foil application, vital for maintaining quality in large-scale operations. Next, the speed and efficiency of the machine can significantly impact your output. Machines that offer adjustable speed settings provide flexibility for different project requirements, ensuring you can handle both bulk orders and intricate designs effectively.

Tips: Look for machines with user-friendly interfaces and automated settings. These features can reduce setup times and minimize the learning curve for your team, making it easier to operate the equipment efficiently. Additionally, investing in machines with robust build quality will reduce maintenance costs and downtime, ultimately enhancing your productivity.

As the global copper foil market continues to grow, projected to increase from $7.67 billion in 2024 to $14.11 billion by 2032 at a CAGR of 7.9%, having a reliable hot foil embossing machine becomes increasingly crucial for businesses looking to capitalize on this upward trend. Ensure that your equipment choice aligns with the quality and efficiency standards needed to succeed in this competitive landscape.

When considering a hot foil embossing machine for your business, it's essential to first assess your specific needs. Factors such as production volume, materials to be used, and the types of designs you wish to create should all play a crucial role in your decision-making process. For small businesses or startups, a compact and user-friendly model may be ideal, while larger operations may require more advanced machinery capable of handling high volumes and diverse materials.

**Tips:** Before purchasing, conduct a thorough analysis of your production requirements. Create a list of the types of projects you'll be working on, as well as the average quantities you'll need to produce. This will help you to choose a machine that can efficiently meet your demands without overwhelming your budget.

Additionally, consider the space available in your workspace. Some machines are large and may require additional accessories or tools that take up extra room. It’s vital to measure both the machine’s dimensions and your available space to ensure a good fit.

**Tips:** Always check the specifications of the machine and compare them against your operational constraints. Furthermore, look into customer reviews and ask for demonstrations when possible, as firsthand experience can provide invaluable insights into usability and performance.

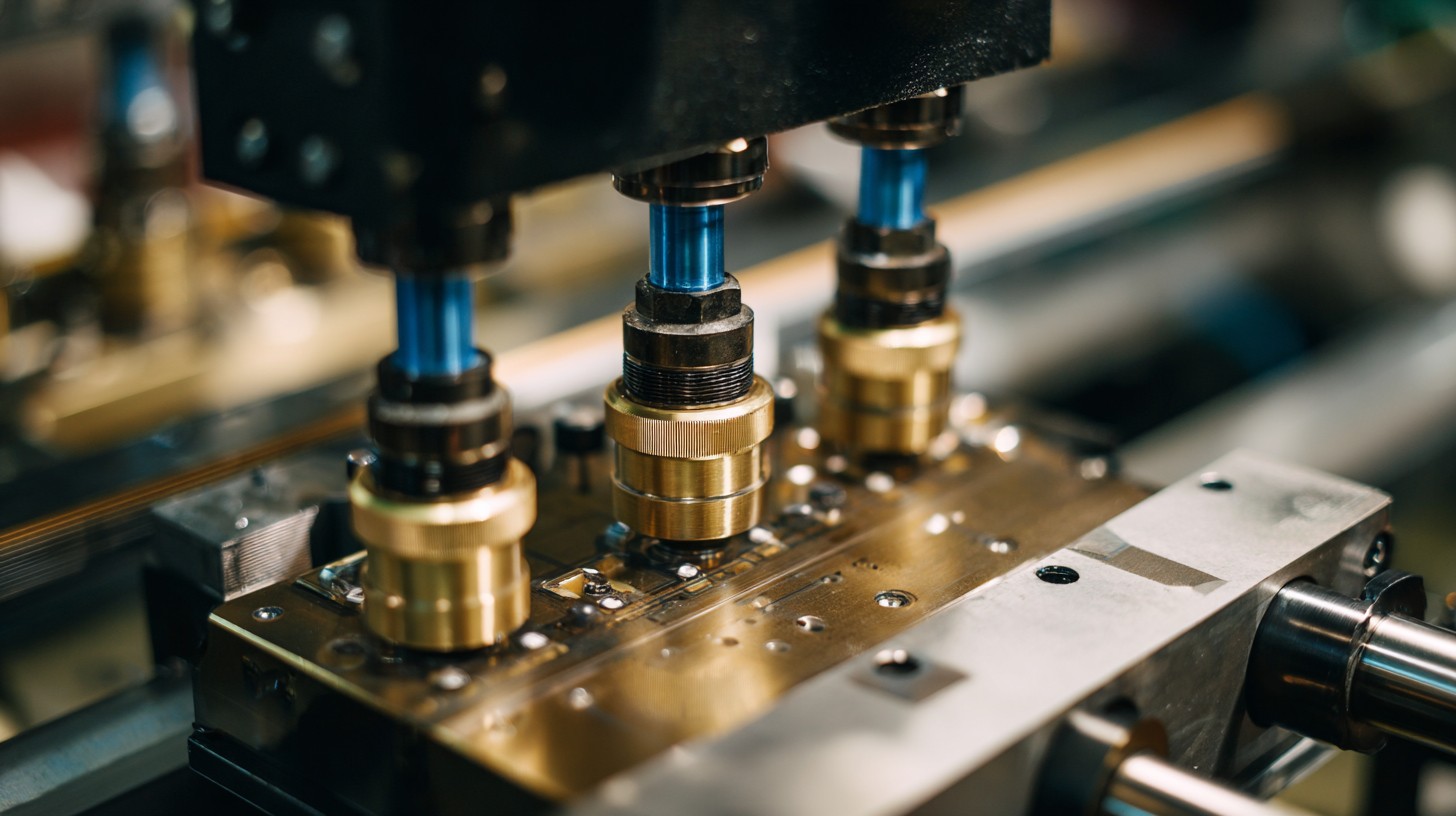

When selecting the best hot foil embossing machine for your business needs, it's crucial to compare different brands and models. Each manufacturer offers a unique set of features that can impact your productivity and the quality of your finished products. For instance, some brands focus on user-friendly controls and digital interfaces, which can streamline the operation process, while others may prioritize robust, heavy-duty construction for high-volume production.

Additionally, consider the variety of foil compatibility and the size capabilities of each model. Brands like L letterpress machines may offer versatile platforms that handle a range of foil types and sizes, making them suitable for diverse applications. On the other hand, machines from companies such as Foilcraft could provide specialized functions for niche markets. By thoroughly evaluating these factors, you can find the hot foil embossing machine that aligns with your specific business needs and production goals.

When considering the purchase of a hot foil embossing machine for your business, budgeting becomes a crucial aspect. First, you need to determine the initial costs, which typically include the machine's price, any necessary accessories, and initial supplies. Quality hot foil embossing machines can vary significantly in price, so it’s essential to assess your budget against the features and capabilities you require. If your workload is high or the complexity of your tasks is substantial, investing in a more advanced machine may save you money in the long run through increased efficiency and reliability.

In addition to the purchase price, it is vital to account for ongoing maintenance and supply costs. Regular maintenance is necessary to ensure optimal performance and longevity of your machine, which can include routine cleaning, servicing, and the replacement of worn-out parts. Moreover, factor in the cost of foil, plates, and other consumables needed for your production process. By carefully outlining both initial and recurring expenses, you can establish a realistic budget that aligns with your business needs and helps maximize your return on investment.