Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

When it comes to enhancing your business's operational efficiency, selecting the right Packaging Printing Machine is a critical decision that should not be taken lightly. The packaging industry is constantly evolving, driven by advancements in technology and changing consumer expectations. As a result, the need for a reliable and efficient printing solution has never been more pressing. A Packaging Printing Machine that aligns with your business needs can significantly improve productivity, reduce costs, and ensure high-quality output that meets market demands.

In this context, there are several key considerations to keep in mind when evaluating different options. Factors such as print quality, speed, versatility, and operational costs play essential roles in determining which machine will best serve your company's requirements. Additionally, understanding the long-term benefits, maintenance needs, and the specific materials you intend to use will provide a clearer picture of what features are essential for your printing operations. By carefully assessing these aspects, businesses can make informed decisions that not only enhance their packaging processes but also contribute to overall growth and competitiveness in their respective markets.

When selecting a packaging printing machine, various key factors must be analyzed to ensure that the choice aligns with your business needs and goals. First, evaluate the machine's printing technology, such as flexography, digital, or offset printing. According to a recent industry report from Smithers Pira, digital printing is expected to grow by 11% annually, driven by the demand for short-run and customized packaging solutions. This growth makes it critical to assess whether a digital machine’s capabilities match your production needs, particularly for personalization and variable data printing.

Another essential consideration is the machine's production speed and capacity. Businesses need to calculate their average output requirements, factoring in peak seasons and planned product launches. Data from the Packaging Machinery Manufacturers Institute (PMMI) indicates that high-speed printing machines can significantly reduce turnaround times, enhancing customer satisfaction and competitive edge. It's crucial to choose a machine that can maintain consistent quality even at higher speeds.

**Tips:**

When analyzing different options, consider visiting production facilities to see the machines in action. Engaging with current users can provide insights into real-world performance and maintenance needs. Additionally, factor in the support and service offered by the manufacturer, as quick responses to issues can save considerable downtime.

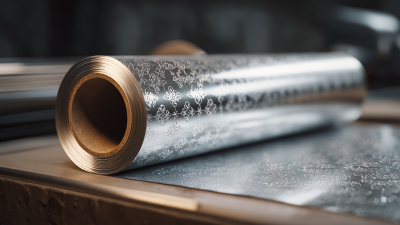

When selecting a packaging printing machine for your business, understanding the different types of packaging printing technologies is crucial. The main types include flexography, gravure, digital printing, and offset printing, each offering unique advantages tailored to specific needs. Flexography, which employs flexible relief plates, is particularly well-suited for high-volume production and versatile applications, making it a preferred choice for large-scale packaging operations. According to the Smithers Pira report, flexographic printing accounts for approximately 40% of global packaging printing volume by using fast-drying inks that can print on various substrates.

Gravure printing, on the other hand, excels in producing high-quality images and consistent color across long runs. Its use in flexible packaging, such as food and beverage containers, is significant, with forecasts indicating that gravure will continue to hold a strong market share, especially in industries demanding durability and vibrancy. Additionally, digital printing technology has rapidly evolved, with a growth rate of around 20% annually, as it meets the increasing demand for shorter print runs and customization. This growth is driven by advancements in inkjet and laser technologies, allowing for quicker production times and greater design flexibility without the need for extensive prepress setup.

Each of these technologies presents distinct characteristics, from production efficiency to print quality, thereby influencing the overall cost and turnaround time. Businesses must weigh these factors in relation to their specific packaging needs, target market, and budget. As the packaging industry continues to innovate, staying informed about these technologies can lead to more strategic investment and operational success.

When evaluating packaging printing machines for your business, understanding your production volume requirements is crucial. The capacity of a printing machine should align with both your current needs and your future growth projections. Begin by estimating your average monthly output, considering factors such as order frequency, product variety, and potential market expansion. This assessment will help you determine whether you need a high-capacity machine that can handle large volumes or a smaller, more flexible option that accommodates shorter runs.

Additionally, think about the scalability of the equipment. As your business evolves, your production demands may shift, requiring you to ramp up output or diversify your product lineup. Selecting a machine that can accommodate varying production volumes, possibly featuring adjustable speeds or modular capabilities, can provide significant advantages. By focusing on these volume requirements during the selection process, you can ensure that the packaging printing machine you choose will effectively support your business objectives and enhance operational efficiency as you grow.

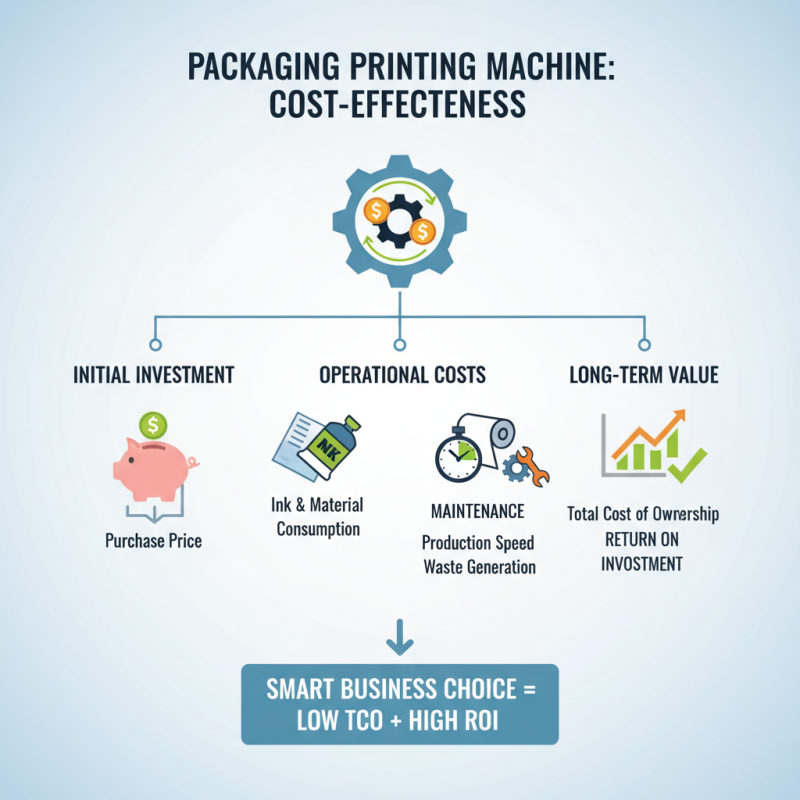

When evaluating a packaging printing machine, the first critical consideration is the cost-effectiveness relative to your business needs. Analyzing the total cost of ownership, including initial purchase price, maintenance expenses, and operational costs, is essential. Businesses should look beyond the upfront investment and consider factors such as ink and material consumption, speed of production, and potential waste generated during the printing process. By calculating the long-term operational expenses, companies can better gauge the true cost and determine whether the machine will yield a significant return on investment.

Budget constraints are another vital factor when selecting a printing machine. Companies must align their purchasing decisions with available financial resources while ensuring that the chosen equipment can meet their production requirements. Conducting a thorough market analysis to compare different machines within the budget can uncover options that offer optimal capabilities without exceeding financial limits. Furthermore, it's beneficial to consider financing options, leasing agreements, or second-hand machines that can provide more flexibility and help manage budgetary challenges effectively. Balancing cost with the desired quality and production efficiency can lead to a well-informed decision that supports the business's overall growth and sustainability.

When selecting a packaging printing machine, understanding the key features and capabilities that align with your business needs is crucial. One of the essential considerations is print quality. A machine that offers high resolution and vibrant color options will enhance your product’s visual appeal, making it stand out on shelves. Additionally, the ability to print on various materials, such as plastic, paper, or eco-friendly substrates, can greatly expand your packaging options and meet diverse customer preferences.

Another vital factor to examine is production speed and efficiency. A machine that can operate at higher speeds can significantly reduce turnaround times, allowing businesses to meet tight deadlines. Furthermore, features like automated job changeovers and user-friendly interfaces contribute to streamlined operations, minimizing the need for extensive operator training. Lastly, consider the machine's scalability; as your business grows, your packaging needs may evolve, and having a machine that can adapt to different requirements without substantial additional investment is a vital long-term consideration.

| Feature | Description | Importance Level | Typical Cost Range |

|---|---|---|---|

| Printing Technology | Types such as flexo, offset, digital, etc. | High | $10,000 - $500,000 |

| Print Speed | Measured in units/hour | Medium | $5,000 - $200,000 |

| Color Accuracy | Ability to match PMS colors | High | $2,000 - $100,000 |

| Material Compatibility | Types of substrates that can be printed on | High | $1,000 - $50,000 |

| Automation Features | Degree of automated processes | Medium | $10,000 - $300,000 |

| User Interface | Ease of use and training requirements | Medium | $500 - $20,000 |

| Support and Maintenance | Availability of service and parts | High | $1,000 - $15,000 annually |