Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

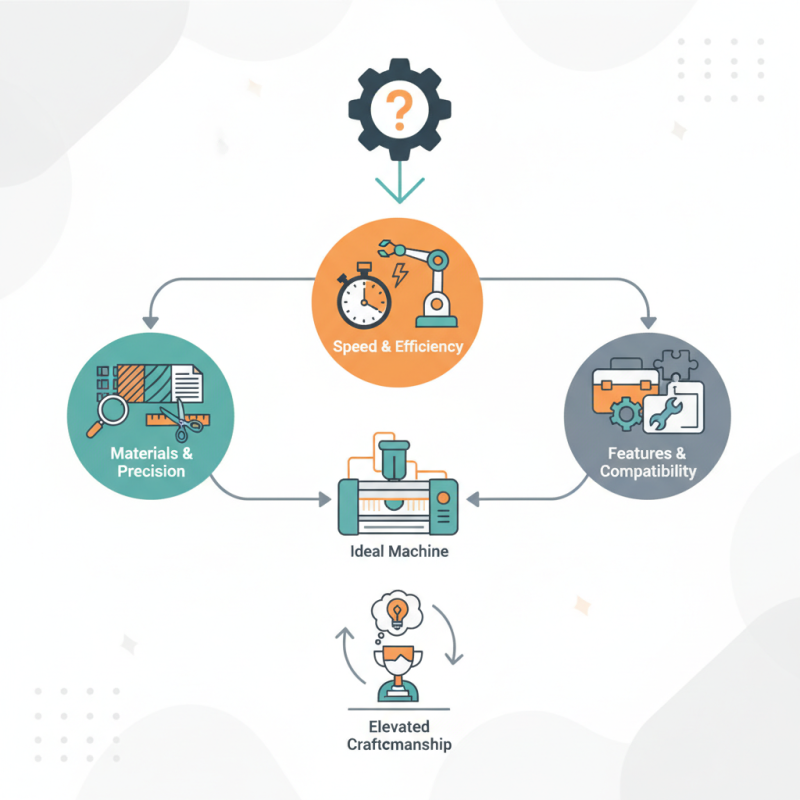

Choosing the right Cutting Machine can greatly impact your projects. Renowned industry expert, Jane Smith, once stated, "The right machine can elevate your craftsmanship." Understanding your needs is crucial.

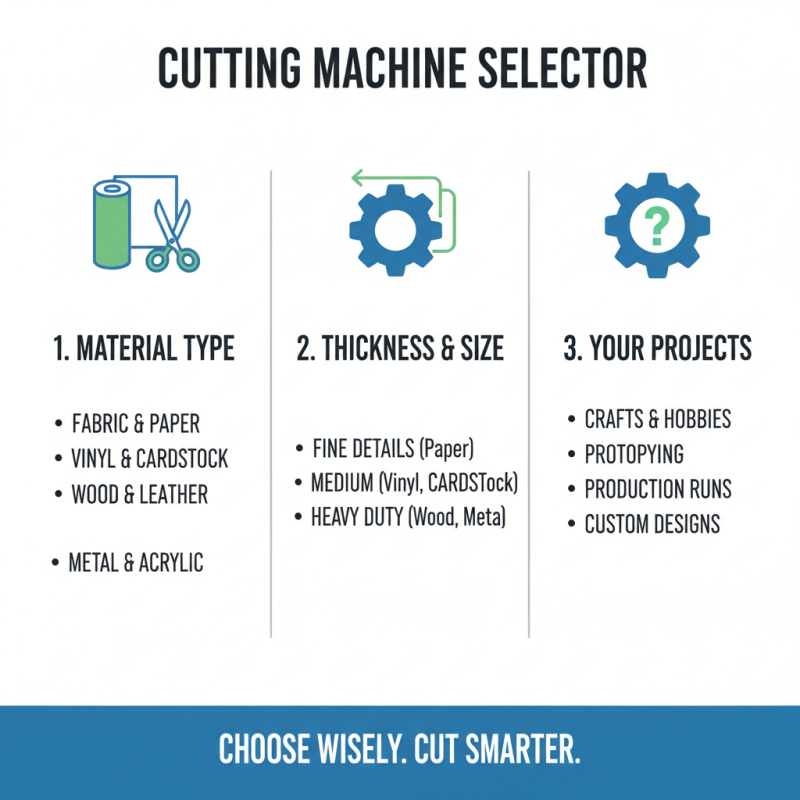

Cutting Machines come in various types and sizes. Each serves different purposes, from DIY tasks to industrial use. Knowing what you need is not always straightforward. Sometimes, choices can be misleading. How do you differentiate between them?

Consider what materials you'll cut most often. Think about the machine's precision and speed. Look for features that suit your specific tasks. Not all machines will fit every situation. Reflect on your current setup and what it lacks. Engage with reviews and seek advice. This process may feel overwhelming at first, but it is essential for making the right choice.

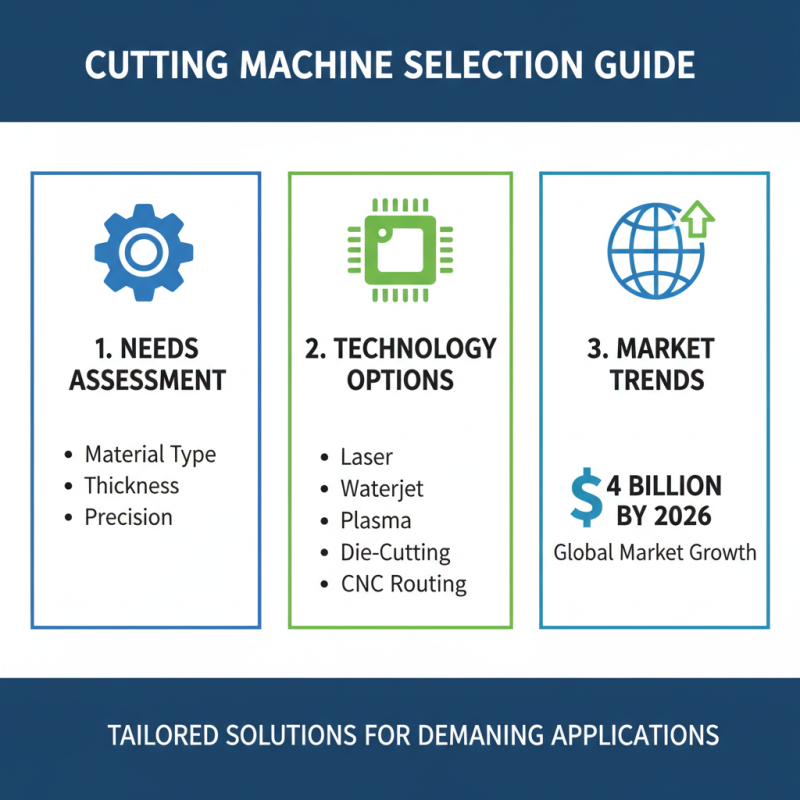

Selecting the right cutting machine requires a deep understanding of your specific needs and priorities. The technology varies widely. Factors such as material type, thickness, and desired precision can significantly impact your choice. The global cutting machine market is expected to reach $4 billion by 2026, showcasing a growing demand for tailored solutions.

One crucial aspect is the power of the machine. Machines with higher wattage can handle thicker materials more efficiently. However, they can also be more complicated to operate. A recent industry report indicated that 48% of users found ease of use as a top priority. Efficiency contributes to productivity, but is there a trade-off with usability?

Budget limitations often dictate choices. A machine that fits your price range might lack some features. It's essential to balance cost-effectiveness and performance. Consider maintenance and operating costs as well. If the machine requires frequent repairs or specialized training, it could lead to frustration. Always weigh short-term savings against long-term investment.

Choosing the right cutting machine can be daunting. There are many options available in the market, each catering to different needs. Understanding the various types is essential. Laser cutting machines, for example, are popular for their precision. According to a recent industry report, the global laser cutting market is projected to reach $5.25 billion by 2026.

Another type is plasma cutting machines. They are excellent for cutting thicker materials. The demand for plasma cutting technology has grown significantly, driven by advancements in automation. In fact, the market for plasma cutting machines is expected to increase at a CAGR of 7.2% during this period. However, plasma machines can be less versatile than laser options.

Water jet cutting machines also deserve attention. They are suitable for a range of materials and offer a clean cutting edge. This type of machine uses high-pressure water to cut, making it particularly effective for fragile materials. Still, their high operational costs might deter many potential users. Balancing efficiency and expenses is key when selecting a cutting machine for specific tasks.

| Type of Cutting Machine | Material Compatibility | Typical Use Cases | Cut Quality | Price Range |

|---|---|---|---|---|

| Laser Cutting Machine | Metal, Wood, Acrylic | Precision Cutting, Engraving | High | $5,000 - $50,000 |

| CNC Cutting Machine | Metal, Wood, Plastic | Industrial Manufacturing | Very High | $10,000 - $100,000 |

| Plasma Cutting Machine | Metal | Auto Repair, Fabrication | High | $1,500 - $30,000 |

| Waterjet Cutting Machine | Metal, Glass, Stone | Stone Cutting, Aerospace | High | $25,000 - $300,000 |

| Die Cutting Machine | Paper, Cardboard, Fabric | Packaging, Crafts | Good | $1,000 - $20,000 |

When choosing a cutting machine, key features can make a big difference. The type of material you plan to cut is crucial. Different machines cater to various materials, from fabric to wood. Check if the machine fits your specific needs. For example, a machine designed for thin paper won’t work well on thicker materials.

Consider the cutting capacity, too. This determines how large a piece you can work on at once. A smaller capacity may limit your projects. Also, think about the blade quality. A dull blade can lead to mistakes. Regular maintenance is needed to ensure optimal performance.

Don't forget ease of use. Some machines come with complex settings that may confuse beginners. A user-friendly interface is essential, especially if you’re new. You also want to look closely at the software compatibility. Make sure it supports your design preferences. This helps avoid frustration down the line. Balancing all these factors is challenging. Evaluate your priorities carefully before making a decision.

When budgeting for a cutting machine, consider various factors. The initial cost is just one piece. Maintenance expenses can accumulate over time. According to recent industry reports, maintenance can account for 15-20% of the total cost. This is often overlooked by buyers.

Operational costs also matter. Whether it’s electricity or replacement parts, these costs can add up. Some machines are energy-efficient, while others are not. A good analysis of energy consumption can save you money. Reports indicate that using energy-efficient models can reduce costs by 25% annually.

Lastly, don't forget about software and training. While some machines come with user-friendly interfaces, others may require extensive training. This can lead to additional expenses. Consider these factors before finalizing your decision. It's crucial to reflect on whether your choice matches your true needs.

When choosing a cutting machine, brand reliability matters. A reliable brand ensures your investment is safe. Look for manufacturers with a solid history. Check their reputation through online reviews. Don't just focus on product features; focus on how the brand supports users.

Customer support can be crucial. If something goes wrong, you need assistance quickly. Evaluate the responsiveness of the support team. How quickly do they answer queries? Check if they provide comprehensive guides and tutorials. A good support system enhances your experience.

Tips: Always consider warranty options. A long warranty reflects brand confidence. You might also want to test the machine before buying. Visit a dealer to see its performance firsthand. Remember, sometimes, it’s better to choose a simpler model with solid support than a complex one that is hard to fix.