Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

Choosing the right Stamping Machine can significantly impact your production quality. Industry expert John Smith once said, "Investing in the right equipment is crucial for success." With countless options on the market, making the right choice might seem overwhelming.

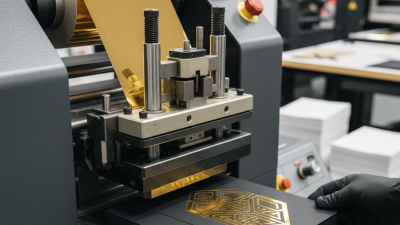

Several factors come into play. For instance, the type of material you will be stamping affects your machine choice. A heavy-duty Stamping Machine may be necessary for thicker materials. However, this can be more expensive and might require scaffolding for support. Also, think about the machine's operational speed. A faster machine could boost productivity, but could also lower precision.

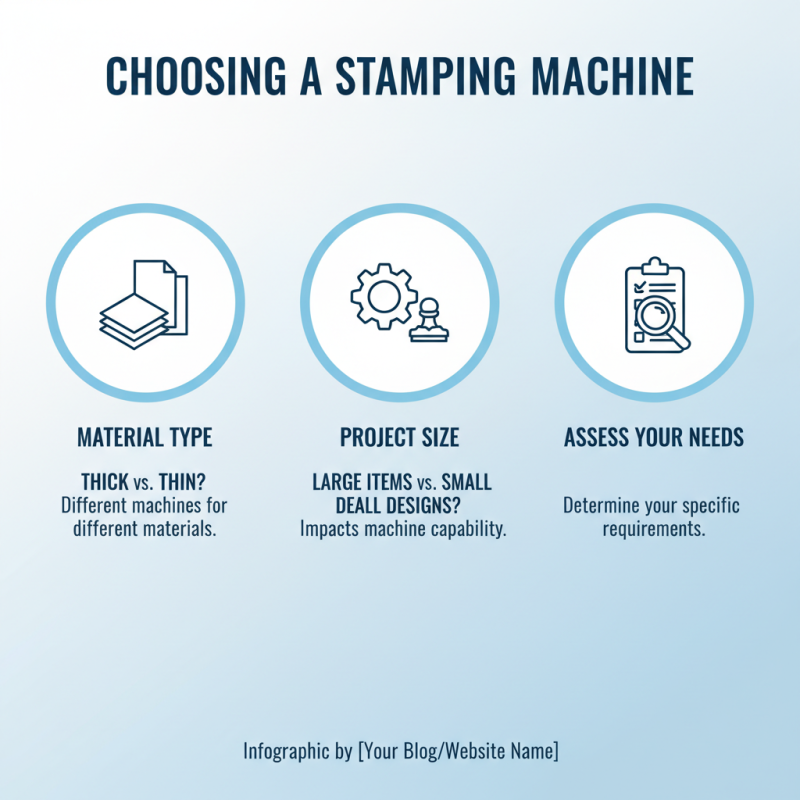

Consider your specific needs and budget. It’s easy to get lost in features and specifications. Reflecting on what truly matters for your projects will lead to a more informed decision. A well-chosen Stamping Machine can enhance output but requires thoughtful consideration.

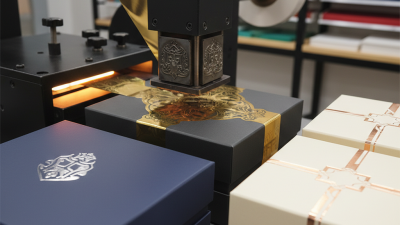

When exploring stamping machines, understanding the various types available is essential. There are manual, semi-automatic, and fully automatic machines. Manual machines are ideal for small projects. They require physical effort, which can be tiring. On the other hand, semi-automatic machines offer a balance. They reduce labor intensity but still require some manual input.

Fully automatic machines provide high efficiency. They can handle large volumes without much supervision. However, these machines are often expensive and complex. A user may feel overwhelmed by their features. It's crucial to assess your production needs. Sometimes, a simpler machine works better for smaller tasks.

Before making a decision, consider the materials you will be stamping. Different machines have varying capabilities. Some may not perform well with thicker materials. Take time to evaluate each option thoroughly. Explore both pros and cons. Time spent researching can prevent future regrets. It's essential to find a machine that fits your specific requirements.

This chart illustrates the frequency of usage for different types of stamping machines in the market. Mechanical stamping machines are the most commonly used, followed by hydraulic and pneumatic options, while electric and manual machines are utilized less frequently.

When choosing a stamping machine, it’s essential to assess your specific stamping needs. Think about the materials you will be using. Are they thick or thin? Different machines can handle various material types. Consider the size of your projects. Will you be working on large items or small, intricate designs? This directly impacts the machine’s capabilities.

Tips: Always gather information about different stamping machines. Review their specifications carefully. Try to envision how each machine would fit into your workspace. It’s easy to overlook space requirements, which could lead to operational challenges later on.

Reflect on the types of projects you plan to take on. Are they one-off designs or mass production? This influences the durability and speed needed in a stamping machine. Make sure to test a machine’s efficiency before making a purchase. It should meet not only your current needs but also future aspirations. Balancing these factors is often tricky but necessary to find the perfect fit.

When selecting a stamping machine, several key features must be considered. The machine’s durability is critical. A robust design often indicates a long lifespan, reducing the need for frequent replacements. Industry reports suggest that a well-built stamping machine can last up to 10 years with proper maintenance. This can save businesses significant costs over time.

Speed is another important factor. High-speed stamping machines average around 200 to 300 strokes per minute. Such efficiency can make a big difference in production output. However, it’s crucial to ensure that higher speed does not compromise accuracy. Inaccuracy can lead to material waste and increase your total production costs.

Furthermore, flexibility is vital. A machine that can handle different materials, such as metal and plastic, increases its utility. Data shows that versatile machines are 40% more efficient, serving various production needs. Yet, users should be cautious about complexity. A machine packed with features might seem appealing, but it could become overwhelming. The right balance of features suited to your specific needs is essential for operational success.

When choosing a stamping machine, budget plays a crucial role. Understanding costs can be challenging. Prices vary widely across models and features. A basic machine may cost a few hundred dollars, while advanced models can exceed thousands. This variance is primarily due to capabilities, durability, and production speed. It’s essential to assess your needs carefully.

Think about your production goals. Will you use the machine frequently? If so, consider investing more upfront. A higher-quality machine may save you money in the long run. Alternatively, a cheaper machine could be tempting. Yet, it may lead to frustrations and extra costs later. Sometimes, the decision comes down to balancing quality with budget constraints.

Additionally, factor in ongoing costs like maintenance and supplies. A low purchase price can hide expenses that accumulate over time. Some machines require specific materials or maintenance routines. Research these elements before committing. Be mindful of potential hidden costs that could alter your calculations. It’s crucial to evaluate the total cost of ownership before making any decisions.

| Machine Type | Price Range | Max Stamping Size (inches) | Material Compatibility | Ideal Use Cases |

|---|---|---|---|---|

| Manual Stamping Machine | $200 - $500 | 3 x 5 | Paper, Cardstock | Crafting, Custom Invitations |

| Electric Stamping Machine | $500 - $1,500 | 4 x 8 | Paper, Leather, Fabric | Mass Production, Custom Designs |

| Die-Cutting Stamping Machine | $300 - $1,000 | 5 x 10 | Paper, Cardstock, Soft Metals | Crafts, Scrapbooking, DIY Projects |

| Heat Transfer Stamping Machine | $400 - $1,200 | 12 x 15 | Textiles, Vinyl | Textile Printing, Apparel Customization |

| Laser Stamping Machine | $1,500 - $5,000 | Variable | Wood, Acrylic, Leather, Metal | Engraving, Custom Marking |

When selecting a stamping machine, researching customer reviews is crucial. These reviews provide real experiences from users. Reading about both positive and negative feedback helps to form a balanced view. Pay attention to details, such as durability and user-friendliness. Some machines may look great on paper but fail in practice.

Brand reputation can be misleading. A popular brand isn’t always the best option. Sometimes, lesser-known brands offer better value for money. Customer reviews often highlight these hidden gems. Look for comments about reliability and ease of use. Photos shared by users can also serve as a valuable reference.

Consider your specific needs. Not every stamping machine suits everyone. Features that appeal to some might not work for your projects. Take time to reflect on what you need most. Be ready to read multiple reviews for a broader perspective. This approach allows for more informed decisions. A thoughtful evaluation can save time and ensure satisfaction.