Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

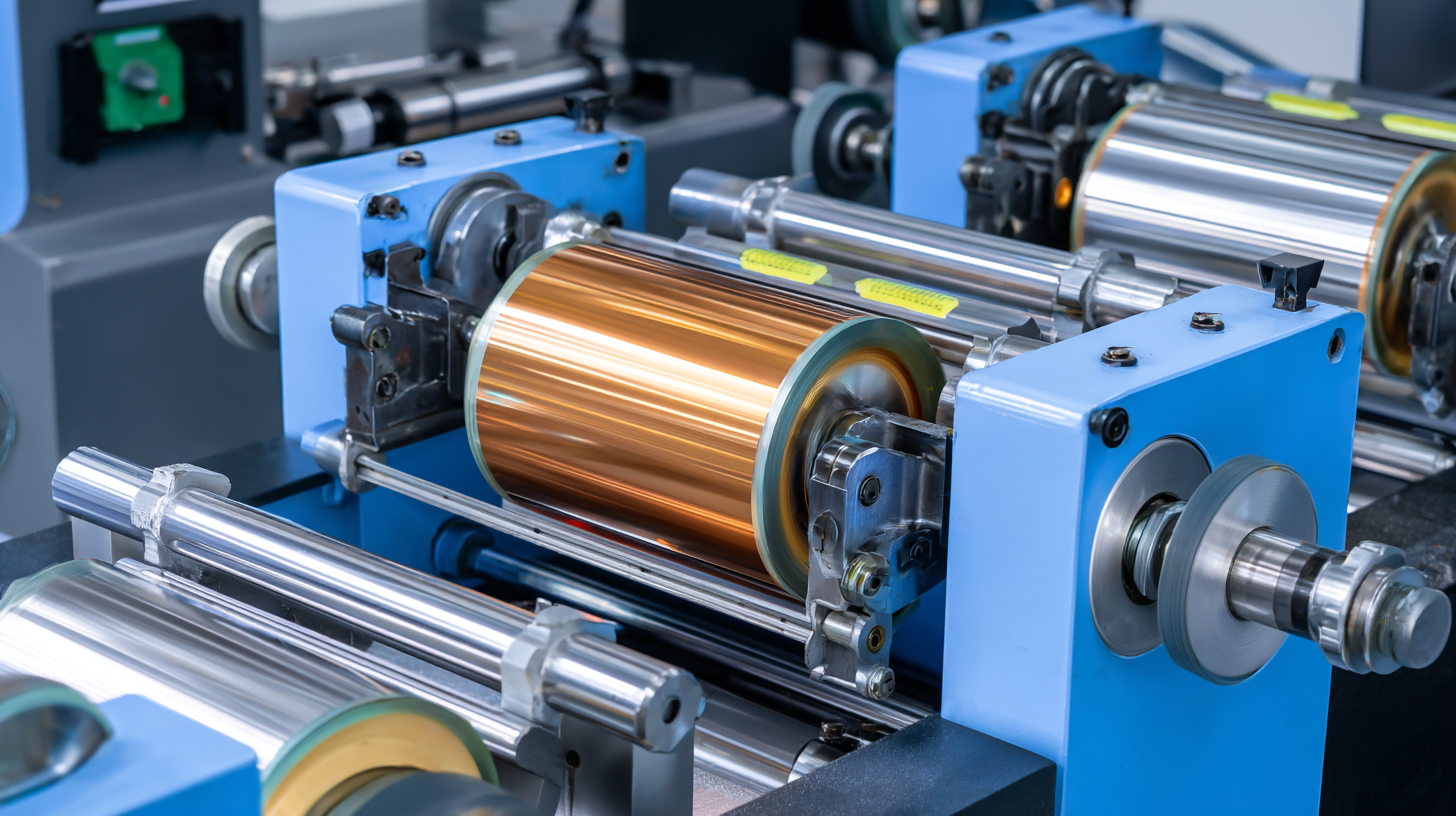

In today's highly competitive manufacturing landscape, optimizing production efficiency is crucial for success. One key innovation that has garnered attention is the Foil Cutting Machine, which has been shown to significantly enhance productivity in various sectors, particularly in packaging and printing. According to a report by MarketsandMarkets, the global packaging machinery market is projected to grow to $45.76 billion by 2027, with automation being a critical driver of this growth.

The Foil Cutting Machine, with its precision cutting capabilities and reduced waste, is at the forefront of this trend, facilitating faster turnaround times and higher output rates. By adopting advanced foil cutting technology, businesses can not only streamline their production processes but also improve product quality and reduce operational costs. This article will explore effective strategies for utilizing the Foil Cutting Machine to maximize production efficiency and drive business growth.

Foil cutting machines are essential tools in the manufacturing sector, designed to enhance production efficiency significantly. Understanding the fundamentals of how these machines operate can optimize their performance. For instance, the precision cutting capabilities of foil cutting machines enable manufacturers to achieve tolerances as tight as 0.01 mm, which is crucial in industries where accuracy is non-negotiable. Reports indicate that adopting high-quality cutting technology can improve production speed by up to 40%, reducing waste and maximizing material utilization.

Moreover, the importance of regular maintenance and operator training cannot be overstated. Studies have shown that organizations that invest in comprehensive training programs for their operators can experience a 25% increase in machine uptime. Utilizing advanced software to monitor machine performance and predict maintenance needs can also lead to a decrease in unexpected breakdowns, enhancing overall productivity. As the industry evolves, staying informed about the latest technological advancements is key to maintaining optimal performance in foil cutting operations.

| Parameter | Value | Impact on Efficiency |

|---|---|---|

| Cutting Speed (m/min) | 30 | High - Increased production output |

| Material Thickness (mm) | 0.1 - 1.0 | Moderate - Affects cut precision |

| Power Consumption (kW) | 5 | Low - Reduces operating costs |

| Setup Time (min) | 15 | Moderate - Impacts overall productivity |

| Maintenance Frequency (weeks) | 4 | High - Prevents downtimes |

When selecting a high-quality foil cutting machine, one must prioritize certain key features that directly impact production efficiency. Firstly, look for precision cutting capabilities. A machine with advanced cutting technology ensures that the foil is cut accurately without damaging the material. This not only minimizes waste but also enhances the overall quality of the final product, which is crucial for industries reliant on precision such as packaging and electronics.

Another essential feature is the machine's speed and throughput. High-quality foil cutting machines should offer rapid cutting speeds while maintaining a consistent level of precision. This dual capability allows for greater production rates and less downtime between cuts, which significantly boosts operational efficiency. Additionally, consider the ease of operation and maintenance. Machines that come with intuitive controls and require minimal maintenance will lead to higher productivity and less labor cost over time, making them a wise investment for any production line.

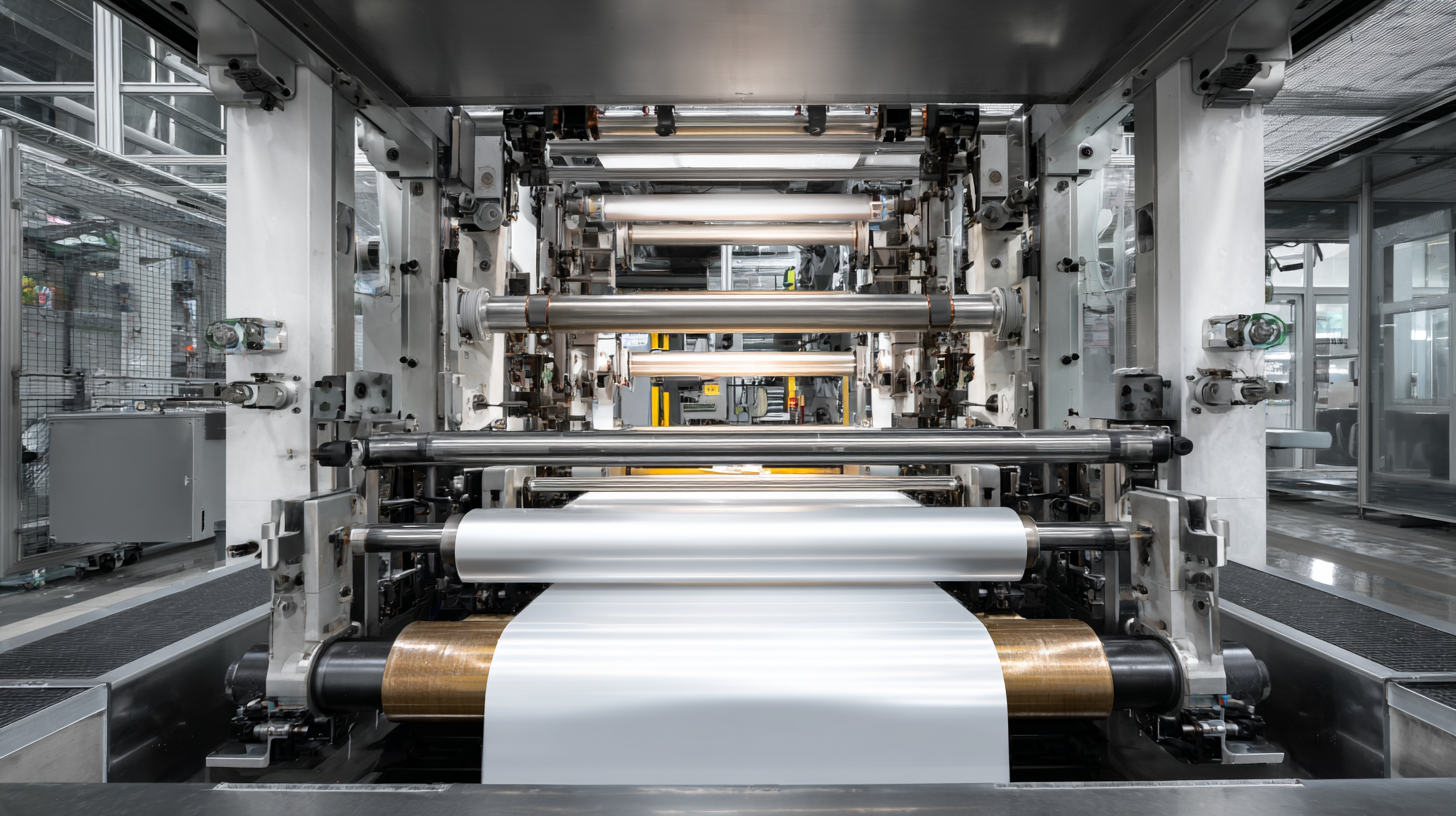

Optimizing production efficiency in manufacturing can significantly benefit from the implementation of foil cutting technology. One of the primary strategies to enhance workflow efficiency is the integration of automated systems that streamline the cutting process. By utilizing advanced software for precision cutting, businesses can reduce material waste and ensure that every piece of foil meets exact specifications. This not only optimizes the use of resources but also minimizes downtime related to quality control.

Another effective strategy is the establishment of a systematic workflow that integrates the foil cutting machine with other production stages. By aligning operations such as storage, handling, and finishing, manufacturers can create a seamless flow of materials. Implementing real-time monitoring systems further enhances this process by allowing operators to track production speed and identify bottlenecks quickly. Moreover, regular training sessions for staff on utilizing the machine efficiently can lead to improved handling and maintenance, which ultimately drives productivity and reduces operational hiccups.

This chart represents the production efficiency (in units produced per hour) over a span of six months when using a foil cutting machine. The data highlights the impact of optimization strategies on workflow efficiency.

Regular maintenance is essential for foil cutting machines to ensure consistent productivity and avoid unexpected downtime. One crucial aspect is keeping the machine clean. Dust and foil remnants can accumulate and affect performance. It’s advisable to regularly wipe down the machine components and perform a thorough cleaning of the cutting area after each shift.

Regular maintenance is essential for foil cutting machines to ensure consistent productivity and avoid unexpected downtime. One crucial aspect is keeping the machine clean. Dust and foil remnants can accumulate and affect performance. It’s advisable to regularly wipe down the machine components and perform a thorough cleaning of the cutting area after each shift.

Another key maintenance tip involves regularly checking the blades for sharpness and wear. Dull blades can lead to inefficiency and poor cutting quality, resulting in waste. Schedule monthly inspections to assess blade condition and replace them as needed to maintain optimal performance.

Lastly, don’t overlook lubrication. Proper lubrication of moving parts reduces friction and wear, extending the machine's lifespan. Create a lubrication schedule that aligns with your operational hours and ensure that all necessary parts receive adequate oil. By adhering to these maintenance tips, you can significantly enhance the reliability and efficiency of your foil cutting operations.

Investing in a foil cutting machine can significantly enhance production efficiency, but the true potential of this equipment is realized only when staff is adequately trained. Best practices for training staff focus not only on operational skills but also on fostering a culture of continuous improvement. Empowering employees to understand the machine's capabilities and limitations can lead to more effective use and reduced downtime.

Tips: Create a comprehensive training program that includes hands-on demonstrations and simulated operation scenarios. Incorporate regular assessments to ensure that staff can effectively troubleshoot common issues, which will enhance their confidence and competence when using the machine.

Another key strategy is to encourage open communication among team members. Regular meetings can be held to discuss any challenges faced during production and share successful practices. This collaborative approach not only helps in addressing issues promptly but also nurtures an environment where team members feel valued and motivated to improve their skills.

Tips: Implement a mentorship system where experienced operators can guide newer staff, bridging the knowledge gap and fostering teamwork. Providing opportunities for continuous learning through workshops or training sessions can further optimize machine utilization and overall production efficiency.